CNC Servo Electric Press Brake, with E-brake

The electric CNC brake press is integrated with the highest technology. Its transmission components are high quality and suitable for high loads.

- Industry 4.0 Ready

Connected with LAN and ERP

Remote assistance and diagnostics

Simple and user-friendly HMI - New Design

Updated Design

New coded security doors

High-gloss anti-dirt water-based paint - Green Hybrid Servo

Up to 80% energy saving

100% electrical

Maximum return on your investment - High Performance

More than 35% higher productivity

Ram speed: 200 mm/s

X-axis speed: 500 mm/s

Heavy-duty ball screw drives

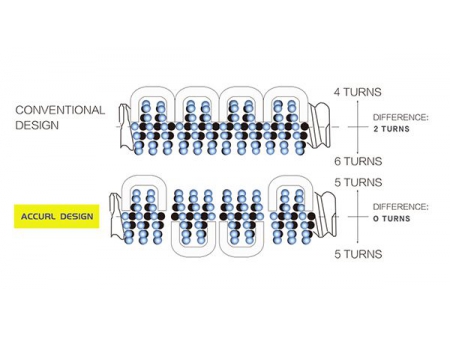

Heavy-duty ball screw drives features d/n circulation route design. The high quality stop accuracy by AC servo motor and ball screw for unequalled ram positioning ±0.001mm.

- High Performance

The high capacity ball screw has larger sphere diameter in higher quantity. The recirculation pipes are located at 180° , ensuring a better load distribution. - Low Noise

By gently absorbing the balls in the tangent direction of the spindle axis, the impact of the collision with other components is greatly reduced. Compared to conventional pipe type, noise reduction reaches more than 6dB. - Grease Retention

Thanks to the special profile of the spherical cavity of the screw, and together with the grease retaining seal A1, the grease retention characteristics are greatly improved compared to conventional plastic seals.

The components used in the mechanical transmission ensure high durability while maintaining accuracy over time.

Servo Electric Technology

The ball screw press brake is driven by an AC servo motor and ball screw driving mechanism. It maximizes productivity with high speed ram and high precision repeatability(0.001mm). This driving method is superior to all other electric/hydraulic performance and is quiet in operation.

- Low maintenance

- Energy saving

80 % lower consumption than hydraulic brakes on an average. - Productivity

Thanks to the high dynamic electro mechanic drive system and “IRIS” safety, 35% shorter cycle times on an average - Precision

The beam synchronization is ensured by the control of two independent servo-electric axes. The reading positioning is obtained by two high precision optical linear encoders.

WILA and ROLLERI pneumatic change tooling system, sophisticated on- and off-line programming possibilities and intuitive touch screen machine interface guarantee short set-up times. - High quality

Servo electrically driven upper beam

Absence of thermal influence of hydraulic oil - Low Noise

Allows up to 70% less noise than other machines - Low maintenance cost

Being an electric model, it does not require regular maintenance. In addition, the automatic lubrication system is adopted.

The electric press brake is driven by a combination of heavy duty servo motor and a high performance ball screw. This innovative machine concept combines productivity, accuracy, flexibility and reliability.

Comparative

The fully electric press brake provides great profit. In addition, the GREENER eco-design enables a significant reduction of environmental impacts and energy savings, which results in cost savings at the same time.

High Reliability and Maximum Productivity

- The electric press brake features the advantages of high acceleration, deceleration and fast response of the servo-electric drive system. Compared to conventional press brakes, considerable productivity increase can be reached; the cycle time is reduced by up to 35 %.

- High speed ram stroke by AC servo motor and ball screw drive for fast approach, bending, and return.