Oil-electric Hybrid Press Brake

The oil-electric hybrid press brake is constructed with a proven design, enhancing operating speed, stroke length, and punching capacity. With advanced motion technology, impressively quiet operation, and flexible functionality, it is the ultimate choice for producing complex parts.

- Material Carbon steel, alloy steel, aluminum alloy, copper alloy, high-speed steel, carbide alloy

- Length 10-6000

- Width 10-1500

- Thickness 0.5-20

- Angle 0-180 degrees

- Accuracy 0.1-0.3mm

- Shapes V Shape, U Shape, Z Shape, L Shape

| Model | Nominal pressure (kN) | Worktable length (mm) | Column spacing (mm) (A) | Slide stroke (mm) (B) | Max. opening height (mm) (C) | Throat depth (mm) (D) | Worktable height (mm) | Rapid decent speed (mm/s) | Decent speed (slow speed mode) (mm/s) | Return speed (mm/s) | Main motor power (kW) | Oil tank capacity (L) | Backgauge X-axis stroke (mm) | Weight (T) |

| 500 | 1500 | 1200 | 165 | 420 | 250 | 850 | 250 | 10 | 200 | 5.5 | 180 | 600 | 3.7 | |

| 800 | 2500 | 2100 | 165 | 420 | 250 | 930 | 230 | 10 | 180 | 7.5 | 280 | 600 | 5.8 | |

| 1100 | 3200 | 2700 | 205 | 460 | 400 | 930 | 220 | 10 | 160 | 7.5 | 300 | 600 | 7.8 | |

| 1300 | 3200 | 2700 | 205 | 460 | 400 | 930 | 200 | 10 | 160 | 11 | 300 | 600 | 8.6 | |

| 1700 | 3200 | 2700 | 205 | 460 | 400 | 930 | 180 | 10 | 130 | 11 | 400 | 600 | 10.8 | |

| 2200 | 3200 | 2700 | 205 | 460 | 400 | 930 | 180 | 10 | 130 | 18.5 | 400 | 600 | 11.5 | |

| 2500 | 3200 | 2700 | 250 | 520 | 405 | 900 | 140 | 8 | 100 | 18.5 | 450 | 600 | 16.5 | |

| 3200 | 3200 | 2600 | 250 | 520 | 405 | 900 | 130 | 8 | 100 | 22 | 500 | 600 | 17.6 | |

| 4000 | 3200 | 2600 | 300 | 540 | 405 | 900 | 120 | 7 | 90 | 30 | 650 | 600 | 20.5 | |

| 1100 | 4000 | 3300 | 205 | 460 | 400 | 930 | 220 | 10 | 160 | 7.5 | 350 | 600 | 8.8 | |

| 1300 | 4000 | 3300 | 205 | 460 | 400 | 930 | 200 | 10 | 160 | 11 | 350 | 600 | 9.5 | |

| 1700 | 4000 | 3300 | 205 | 460 | 400 | 930 | 180 | 10 | 130 | 11 | 450 | 600 | 11.5 | |

| 2200 | 4000 | 3300 | 205 | 460 | 400 | 930 | 180 | 10 | 130 | 18.5 | 450 | 600 | 12.8 | |

| 2500 | 4000 | 3300 | 250 | 520 | 405 | 900 | 140 | 8 | 100 | 18.5 | 450 | 600 | 18 | |

| 3200 | 4000 | 3200 | 250 | 520 | 405 | 900 | 130 | 8 | 100 | 22 | 500 | 600 | 19.6 | |

| 4000 | 4000 | 3200 | 300 | 540 | 405 | 900 | 120 | 7 | 90 | 30 | 650 | 600 | 22 | |

| 1700 | 6000 | 5000 | 205 | 460 | 405 | 1250 | 180 | 10 | 110 | 15 | 500 | 600 | 18.8 | |

| 2500 | 6000 | 5000 | 250 | 520 | 405 | 1250 | 180 | 8 | 100 | 22 | 580 | 600 | 22 | |

| 3200 | 6000 | 5000 | 250 | 520 | 405 | 1250 | 130 | 8 | 90 | 26 | 650 | 600 | 28 | |

| 4000 | 6000 | 5000 | 300 | 560 | 405 | 1250 | 120 | 7 | 80 | 30 | 750 | 600 | 36 |

- DA-66T Press Brake Control

The DA-66T press brake control features an intuitive 2D touch-based graphical programming interface, allowing for seamless operation and precision bending. Its 17-inch high-resolution TFT full-color display provides clear visualization, enhancing user experience. Equipped with a comprehensive Windows application suite, it ensures smooth integration with various production workflows. The system is fully compatible with Delem’s modular architecture, offering scalability and flexibility. Additionally, USB and peripheral interfaces enable easy data transfer, while the multi-tasking environment enhances efficiency in user program applications. The angle detection sensor interface further ensures exceptional bending accuracy, making it a powerful tool for modern press brake operations.

- Hybrid ECO Function

The Hybrid ECO Function is an innovative servo-driven system designed for press brakes, enabling precise plunger movement control with minimal oil consumption. Thanks to the servo motor technology, energy efficiency is significantly improved without compromising performance.

A high-quality hydraulic valve system ensures accurate pressure control, while the left and right cylinders operate in perfect synchronization, enhancing stability and longevity. This advanced system provides a long-lasting, efficient, and eco-friendly solution for modern bending operations.

- 4-Axis Press Brake Quick Clamp with X, R, Z1, Z2-Axis

The 4-axis CNC backgauge is equipped with high-precision ball screws and linear guides on the X and R axes, ensuring smooth and accurate positioning. The Z1-Z2 axes feature precision belts and YYC high-accuracy gantry racks, delivering exceptional stability and repeatability.

Designed for precision and efficiency, the backgauge includes finger stops with two-step emergency stop functionality and micron-level adjustment. It offers ±0.03mm mechanical accuracy, with speeds of 1000 mm/s for Z1-Z2 axes and 500 mm/s for the X-axis, optimizing performance for high-speed bending operations.

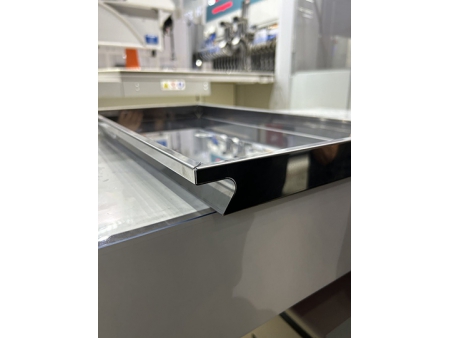

- Press Brake Quick Clamp

The high-precision quick-clamp system features a one-touch die release design with an anti-drop mechanism, ensuring safer and more efficient tool changes. This advanced clamping system enhances productivity and operational safety, making die replacement quick and hassle-free.

- Italian GV Grating Ruler

The Italian GV grating ruler guarantees higher bending accuracy and enhanced safety during operation. Additionally, the laser safety protection system offers superior optical protection while maintaining the highest productivity and performance levels for CNC press brakes.