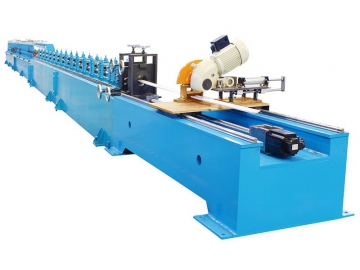

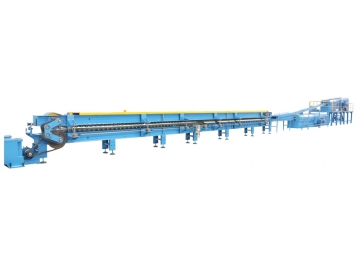

Roller Shutter Garage Door Roll Forming Line

High speed door production line

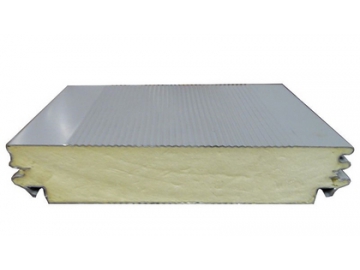

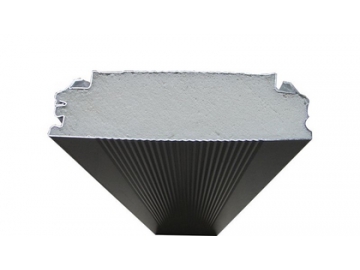

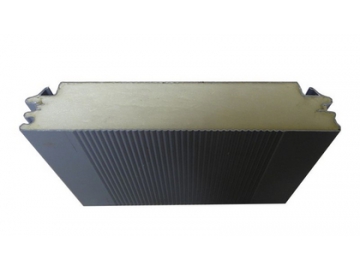

This roll forming line is primarily designed for manufacturing roller shutter garage door that is constructed with PU rigid foam filled slats. With features of good thermal insulation, tight sealing effect and high wind load resistance, the double-skinned PU-foamed industrial doors are widely used as logistic doors, cold room doors, as well as garage doors.

Samples of Finished Product

Due to the door opening speed is up to 2.5m per second, the high-speed doors are typically suited to use in workshop passages and logistics areas where fast access and frequent operations are required. The door panel comprises of two 0.8mm-thick coated steel sheets and an insulation core, the total thickness of the sandwich panel is 40mm, featuring good insulation, light weight, high strength, excellent resistance to impact and wind load of level 12. Compared to common industrial vertical lift doors, industrial roller shutter door can help industrial door manufacturers save approximately 80% save while significantly improving working efficiency.

- Uncoiler (2 sets ×2 tons)

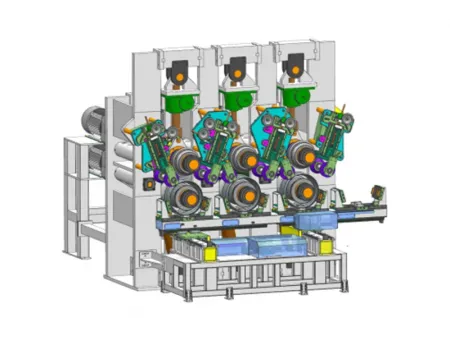

- Roll forming machine

- Low pressure PU foaming machine (SAIP Italy or China Brand)

- Double belt machine (lamination machine)

- Fly saw cutting system with servo motor

- PLC automatic control system

- Runout table

- Coil thickness: 0.7-0.8mm

- Coil width: depending on profiles

- Profile width: 40mm/60mm

- Drive: gearbox with universal joint transmission system/gear transmission system

- Forming stations: 44/46

- Main motor power: 15kW

- Double belt machine: rubber belt with heating system

- Steel sheet roll forming speed: 8-10m/min

- Sandwich panel line speed: 4-6m/min (with foam)

Features

-

This roll forming line adopts the Italian state-of-the-art gearbox transmission system instead of using conventional gearbox drive and chain drive transmission methods. The structure of the entire line is processed using imported gantry machining center and assembled through integral welding technology, providing advantages of low noise level, strong strength, large torque, high precision, fast working speed and stable operation, as well as shortening the length of the roll forming line therefore greatly saving workspace.

-

The forming rolls are made of SKD11 steel that is subjected to processes of rough turning, heat treatment, fine grinding, fine turning and chrome plating, enabling the forming rolls are featured by high strength, good abrasion resistance and corrosion resistance. Generally, these steel forming rolls can withstand abrasion of over 15 years.

-

The adjustment of the roll former can be simply carried out by using adjustment screw, and the scale on the adjustment screw gives a clear indication, ensuring the precision and ease of operation.

Huazhong is committed to the innovation of roll forming machines and helping customers lower their costs and stay ahead in their competitive market.