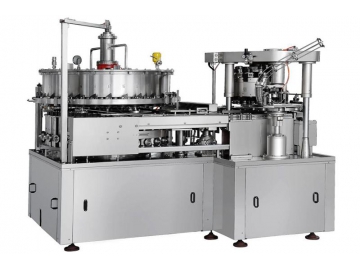

Aluminum Can Immersing & Rinsing Machine

Description

The QXC02 aluminum can immersing & rinsing machine is also called the can washing machine which is the dedicated matching equipment of the aluminum can manufacturing plant. It is used for the internal and external cleanness of the body of the cylindrical shape. This machine is fully automatic equipment. Its in and out of the can, cleanness and drying are all automatic. The conveyor chain immerses the aluminum cans which come out from the surface finishing trimmer into the heated cleaning fluid and finishes the cleanness, rinsing and press-blow of the aluminum cans respectively in five wash tanks. After one strong wash, one cleaning and three rinsing, the aluminum can will leave the wash tank. After the water spray, the aluminum can is driven by the connecting rod to change its direction from horizon to vertical and then enter the drying oven over the wash tank. The circularly heated air dries the aluminum can completely. The QXC02 aluminum can immersing & rinsing machine can both be connected with other equipment and be used independently.

| Applicable can diameter | φ35-φ66mm |

| Maximum applicable can length | 260mm |

| Production speed | 100-120/min |

| Motor power | 5.5KW 1.5KW |

| Thermal power | 75KW 18KW |

| Dimensions | 6300*2946*3850mm |

| Net weight | 8T |

| Drying temperature | 150℃-180℃ |

| Whole wash time | 3.5minutes |

| Drying time | 3.8minutes |

| Aluminum can chain | 78meters |

| Total power | 100KW |

| Chain distance | 76.2mm |

- The sink of the aluminum can immersing & rinsing machine and its outer frame and some other parts all adopt high quality stainless steel so that they have great corrosion resistance. You can adjust the water temperature according to the washing effect.

- The circulation fan can send the air to the work area for circulating heating. The internal temperature of the heating zone is controlled by the temperature controller. You can set the temperature you need freely according to the season and weather changes.

- There are 3 nervous devices in the equipment while it is operating. And they all have proximity switch protection devices to make sure the equipment can be out of service automatically when the chain meets the overload and the text display will display the location of the point of failure in the meantime.

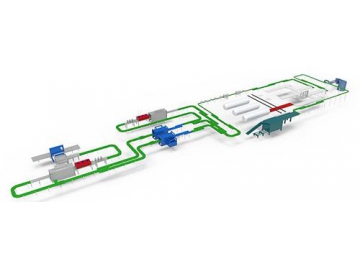

Internal structure

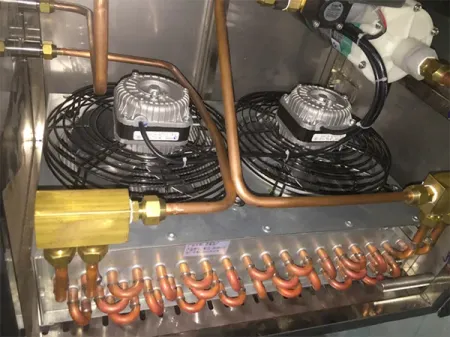

Internal structure  Motor

Motor