Long Plunger Sand-control Subsurface Pump

Oil pump/ Sand-proof pump/ Plunger pump

The long plunger sand-control pump is a sand-proof and anti-blockage pump that can realize sand pumping operation without the worry of breakdown. In oil well operations where the geological structure is loose, and sand content is high, these pumps have a working life 3-5 times that of conventional pumps.

Technical Performances:

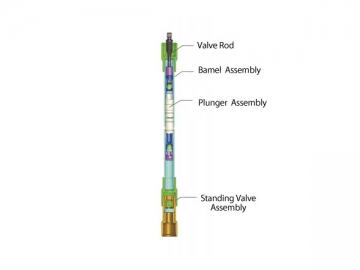

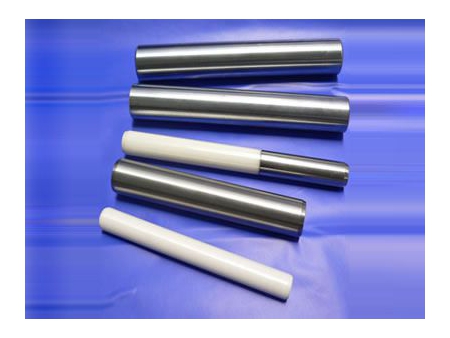

1. The pump barrel machined by using the high quality special-purpose blank, the internal surface has the chrome-plating or the nickle phosphorus compound plating superficial strengthening processing to achieve the good intensity, the rigidity, wear-resistance and anti-corrosion.

2. The plunger surface uses a nickel base alloy powder to spurt welding in order to achieve excellent wear-resistance and prevent corrosion.

3. The valve ball and the valve seat are made using high-carbon chromium stainless steel, ceramics, or tungsten carbide material to achieve a longer life span.

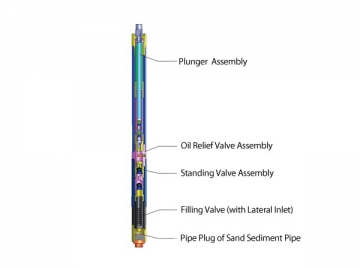

4. The pump features a long plunger, sealed short pump cylinder and a lateral inlet structure. The double cylinder structure creates an annular space for sand setting. The plunger matches the pump cylinder perfectly, effectively preventing sand from flowing into the sealing clearance between the cylinder and the plunger. The hardened surface layer is extremely durable.

5. The flow cross section is enlarged, the upper valve cover is deep inside the pump cylinder. The resistance of oil flow is small, leading to great pump efficiency.

Working Principle:

The sand grain enters the sand setting pipe 11 below the pump and through the ring space between the external sand pump 6 and pump cylinder 3. Some sand grains in the pump cylinder will be brought outside the pump by oil flow due to the short pump cylinder. If pumping is interrupted in the midway, the sand contained in the liquid in the oil pipe of the pump will also enter the sand setting pipe so as to avoid sand blockage.

A batch of GLB 50-21 were sent to Jakarta,Indonesia

Technical Parameters:

| Code Series | Pump Dia mm | Barrel Length,m | Plunger Length,m | Stroke Length m | Thread | Rod Thread | Max Dia mm |

| (FS)25-125TH | φ31.8 | 1.5 | 3.3-6.3 | 2.0-5.1 | 2-7/8"TBG | CYG22 | φ107 |

| (FS)25-150TH | φ38.1 | ||||||

| (FS)25-175TH | φ44.5 | ||||||

| (FS)25-200TH | φ50.8 | ||||||

| (FS)25-225TH | φ56.0 | ||||||

| (FS)25-275TH | φ69.85 | 3-1/2"TBG | φ120 | ||||

| (FS)25-325TH | φ82.5 | 4"TBG | CYG25 | φ140 |