Fishing Standing Valve Subsurface Pump

Standing Valve/ Sucker rod pump/ Plunger pump

The fishing standing valve subsurface pump combines the advantages of the whole barrel subsurface pump and rod pump. It can maintain the standing valve without lifting the pump, significantly reducing operating costs.

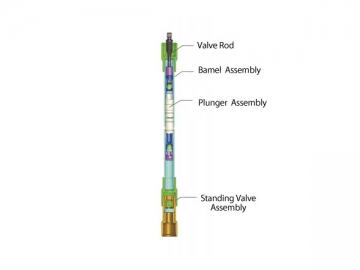

Structure:

The standing valve assembly and the pump cylinder assembly are connected and sealed by a clamp. There is a special structure under the plunger assembly, allowing it to be detached from the standing valve.

When overhauling the standing valve, you should lower the plunger to the bottom of the pump. The rotary sucker rod drives the plunger to rotate. Connecting the bottom of the plunger and the top of the standing valve with a threaded screw, you can remove the standing valve assembly from the pump cylinder assembly by lifting the sucker rod. After the overhaul, the standing valve should be connected to the bottom of the plunger. Then, the plunger will be put into the pump cylinder assembly with the sucker rod through the tubing string. The special structures in the bottom of the pump cylinder assembly and outside the standing valve can clamp and seal automatically. Rotate the sucker rod in the reverse direction to detach the plunger and the standing valve assembly, then the oil extraction can be executed normally.

The pump is individually packaged to ensure safety and avoid damage during transport!

Packaging & Shipping

Oil Pump for Oilfields:

1.Wrap pump with plastic protective film.

2. Separate with stow-wood and fixed by iron bolt.

3. Put into the iron case.

Our Services

Engineering assistance is available.

We offer 24/7 online service

One year guarantee for every product.

Technical Parameters:

| Type | Model | Pump Bore(mm) | Plunger Length(m) | Barrel Length(m) | Tubing OD(mm) | Sucker Rod Diameter(mm) | Extension Length(mm) | Well Condition |

| Tubing Pump | 20/25-106TH | 28.5 | 0.6-2.1 | 3.3-9.5 | 60.3-73.0 | 15.9-19.1 | 0.6-0.9 | The well contains salt,sulfur,CO2,bacilli,corrosive medium and little sand |

| 20/25-125TH | 31.8 | 0.6-2.1 | 3.3-9.5 | 60.3-73.0 | 15.9-19.1 | 0.6-0.9 | ||

| 20/25-150TH | 38.1 | 0.6-2.1 | 3.3-9.5 | 60.3-73.0 | 19.1 | 0.6-0.9 | ||

| 20/25-175TH | 44.5 | 0.6-2.1 | 3.3-9.5 | 60.3-73.0 | 19.1 | 0.6-0.9 | ||

| 25-200TH | 50.8 | 0.6-2.1 | 3.3-9.5 | 73 | 19.1 | 0.6-0.9 | ||

| 25-225TH | 57.2 | 0.6-2.1 | 3.3-9.5 | 73 | 19.1 | 0.6-0.9 | ||

| 30-275TH | 69.9 | 0.6-2.1 | 3.3-9.5 | 88.9 | 22.2 | 0.6-0.9 | ||

| 40-375TH | 95.3 | 0.6-2.1 | 3.3-9.5 | 114.3 | 25.4 | 0.6-0.9 | ||

| Rod Pump | 20-125RH/RW | 31.8 | 0.6-2.1 | 3.3-9.5 | 60.3 | 19.1 | 0.6-0.9 | |

| 20/25-150RH/RW | 38.1 | 0.6-2.1 | 3.3-9.5 | 60.3-73.0 | 19.1 | 0.6-0.9 | ||

| 25-175RH/RW | 44.5 | 0.6-2.1 | 3.3-9.5 | 73 | 19.1 | 0.6-0.9 | ||

| 25-200RW | 50.8 | 0.6-2.1 | 3.3-9.5 | 73 | 19.1 | 0.6-0.9 | ||

| 30-225RH/RW | 57.2 | 0.6-2.1 | 3.3-9.5 | 88.9 | 19.1 | 0.6-0.9 | ||

| Sand Control Pump With Long Plunger | 20/25-125-225TH | 31.8-57.2 | 3.3-6.3 | 1.2-2.1 | 60.3-73.0 | 19.1-12.2 | / | High sand well |

| Bridge Linkage Pump | 25/30-150-225TH | 31.8-57.2 | 0.6-2.1 | 3.3-9.5 | 73.0-88.9 | 19.1-22.2 | / | Long tail pipe or with packer or slant well |

| Slim Hole Pump | 20-125-175TH | 31.8-44.5 | 0.6-2.1 | 3.3-9.5 | 60.3 | 190.1 | / | Casing repair well or Slim hole well |

| Anti-salt pump With Long Plunger | 25-125-225TH | 31.8-57.2 | 3.3-6.3 | 1.2-2.1 | 73 | 19.1-22.2 | / | Severe crystallizing salt well |

| Gas Control Pump | 25-125-225TH | 31.8-57.2 | 1.2-2.1 | 3.3-9.5 | 73 | 19.1 | / | High gas well |

| Heavy Crude Pump Using Liquid Rotary | 25-150/225TH | 31.8-57.2 | 1.2-6.3 | 3.3-9.5 | 73 | 19.1 | / | Heavy crude well |

| 25-175/225TH | 44.5-57.2 | 1.2-6.3 | 3.3-6.6 | 73 | 19.1 | / | ||

| Slant Hole Pump | 25-150-225TH | 31.8-57.2 | 0.6-2.1 | 3.3-9.5 | 73 | 19.1 | / | Limited leaning degree |