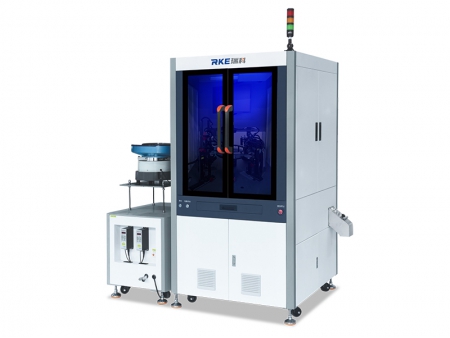

Automatic Screw Optical Sorting Machine, Thread Inspection

- Types:

Glass plate optical sorting machine

- Suited for:

Screws, micro screws, plastic and rubber parts, electronic component and small parts

- Inspection Accuracy:

±0.01mm

- The inspection and sorting speed depends on the feeding system, up to 500-1200 pieces per minute.

The inspection screen comes equipped with three industrial CCD cameras. The CCD1 is a head-up camera used to inspect the multi-segment height and outer diameter of the products. The CCD2 is a vertical bottom view camera used to inspect the cross slot or flat slot on the head of the product. We can add additional 1 to 4 CCD cameras for inspecting thread damage or other defects of the product with a complete 360 degree view.

- CCD1, head-up

- CCD2, vertical bottom view

- CCD2, vertical bottom view

- CCD3-5 thread damage from 360°view

- Model: RK-1500

- Head Outer Diameter (mm): 1-25

- Head Thickness (mm): 1-15

- Total Height (mm): 1-25

- Inspection Accuracy: ±0.01mm

- Air Pressure (Kg/cm²): 5

- Host Computer: Industrial PC

- Digital Camera: Industrial CCD

- Net Weight (KGS): 650

- Dimension (L*W*H) (mm): 1350*1100*1800

Note: Customized service can be provided according to the detect demand.

- Due to the high transparency of glass, this machine can inspect all products that can be placed stably on the glass platform.

- 2 to 6 additional CCD cameras can be installed according to the inspection parameters on your checklist.

- The inspection and sorting speed depends on the feeding system, up to 500-1200 pieces per minute.

- An automatic counting and packing machine and automatic feeder can be added according to your requirements.

- Parts are quickly changed and easy to operate.

-

Strong versatility

This machine is highly adaptable as it can be used to inspect various types of products by simply switching the vibration plate or track. The preparatory functions for inspecting a different product type only takes 30 minutes depending on the skill level of the operator.

-

Inspection accuracy

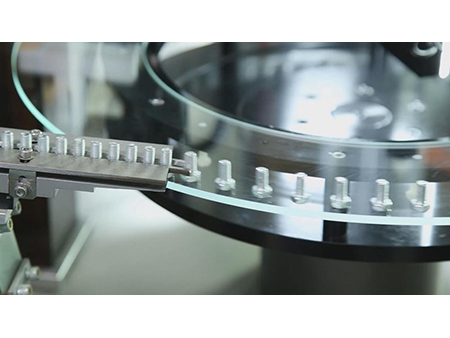

Products will be delivered to the glass inspection platform via a vibration plate and track.

The position of the products will be finely adjusted to reach a fixed position when it is detected and captured by the camera.

That ensures a high level of inspection accuracy.

-

Separate outlet for OK or NG products

This machine has separate OK, NG, and inspection outlets. The filtered product can then be classified.

Uncertain Product

If a product is in an abnormal position such as too close to another product, it will be ejected to the inspection outlet.

- Vibration bowl

- Feeding elevator

- Automated conveyor system