EHM, EGM Heavy Duty Slurry Pump

EHM, EGM Heavy Duty Slurry Pump

EHM and EGM heavy duty slurry pump, as cantilevered centrifugal slurry pump, is widely applicable to mining ,metallurgy, petroleum, chemicals, coal, electricity, transportation, river dredging, building materials ,municipal works and so on for transporting strong abrasive and high concentration of slurry, low concentration and high head of slurry or slurry with low corrosion. Within the maximum allowable range of working pressure of pump, our product can realize the use of multistage cascade.

EGM Series Performance Chart

| Model | Allowable Max Power P( kW ) | Clear Water Performance | Impeller | |||||

| Capacity Q | Head H(m) | Rotate Speed n(r/min) | Top Efficiency η% | NPSH(m) | Impeller Diameter D(mm) | |||

| M 3 /h | I/s | |||||||

| EGM-1C | 30 | 16.2-34.2 | 4.9-9.5 | 25-92 | 1400-2200 | 20 | 2-5.5 | 330 |

| EGM-2D | 60 | 68.4-136.8 | 19-38 | 25-87 | 850-1400 | 47 | 3-7.5 | 457 |

| EGM-3E | 120 | 126-252 | 35-70 | 12-97 | 600-1400 | 50 | 2-5 | 508 |

| EGM-4S | 560 | 324-720 | 90-200 | 30-118 | 600-1000 | 64 | 3-8 | 711 |

| EGM-6S | 560 | 468-1008 | 130-280 | 20-94 | 500-1000 | 65 | 4-12 | 711 |

| Note: 1. Quantity range recommend: 50% Q′≤Q≤110%Q′(Q′ appropriate to capacity at highest efficiency point) 2. NPSH: appropriate to point Q recommended at highest speed. | ||||||||

EHM Series Performance Chart

| Model | Allowable Max Power P( kW ) | Clear Water Performance | Impeller | |||||

| Capacity Q | Head H(m) | Rotate Speed n(r/min) | Top Efficiency η% | NPSH(m) | Impeller Diameter D(mm) | |||

| M 3 /h | I/s | |||||||

| EHM-1B | 15 | 12.6-28.8 | 3.5-8 | 6-68 | 1200-3800 | 40 | 2-4 | 152 |

| EHM-1.5B | 15 | 32.4-72 | 9-20 | 6-58 | 1200-3200 | 45 | 3.5-8 | 184 |

| EHM-2C | 30 | 39.6-86.4 | 11-24 | 12-64 | 1300-2700 | 55 | 4-6 | 214 |

| EHM-3C | 30 | 86.4-198 | 24-55 | 9-52 | 1000-220 | 71 | 4-6 | 245 |

| EHM-3D | 60 | |||||||

| EHM-4D | 60 | 162-360 | 45-100 | 12-56 | 800-1550 | 65 | 5-8 | 365 |

| EHM-4E | 120 | |||||||

| EHM-6E | 120 | 360-828 | 100-230 | 10-61 | 500-1140 | 72 | 2-9 | 510 |

| EHM-6R | 300 | |||||||

| EHM-8ST | 560 | 612-1368 | 170-380 | 11-61 | 400-850 | 71 | 4-10 | 686 |

| EHM-10ST | 560 | 936-1980 | 260-550 | 7-68 | 300-800 | 82 | 6 | 762 |

| EHM-12ST | 560 | 1260-2772 | 350-770 | 13-63 | 300-600 | 77 | 3-10 | 965 |

| EHM-14TU | 1200 | 1368-3060 | 380-850 | 11-63 | 250-550 | 79 | 4-10 | 1067 |

| Note: 1. Quantity range recommend: 50% Q′≤Q≤110%Q′(Q′ appropriate to capacity at highest efficiency point) 2. NPSH: appropriate to point Q recommended at highest speed. | ||||||||

Advantages

1. EHM and EGM series product belongs to heavy duty slurry pump, which adopts thick materials and high chromium alloyed materials of main wear parts, featuring excellent abrasion resistance. Even if working in high abrasive condition, our product still maintains long service life and high performance to price ratio.

2. Besides, with the structure of double casing, our heavy duty slurry pump is easy to disassemble and replace the spare parts with low cost of maintenance.

3. Compared to foreign product in AH and HH of Warman series, our product possesses higher performance to price ratio.

Note

1. This heavy duty slurry pump utilizes three seal types, including packing seal, expeller seal and mechanical seal. If there is no requirement, we normally choose the expeller seal. Otherwise, users should tell us their demands before placing the order.

2. Pump discharge direction is designed to rotating installation according to eight angles. Generally, the discharge is settled upside, or customers can give their requirement according to the specific conditions before purchasing.

3. The drive type of our product falls into direct connection, V-belt drive, gearbox transmission, fluid coupling drive, variable frequency drive and so on.

Model Explanation

E: Excellence

H: Heavy duty slurry pump

M: Anti-abrasive metal lined

8: Discharge Size (inch)

ST: Frame Type

Structural Diagram

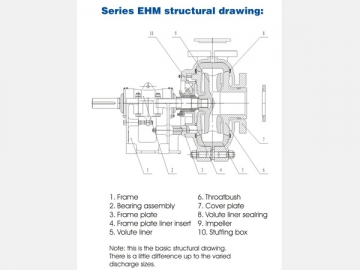

Series EHM structural drawing:

1.Frame 6.Throatbush

2.Bearing assembly 7.Cover plate

3.Frame plate 8.Volute liner sealring

4.Frame plate liner insert 9.Impeller

5.Volute liner 10.Stuffing box

Note: this is the basic structural drawing.

There is a little difference up to the varied

discharge sizes.

Related Names

High Pressure Pump | Industrial Transfer Pump | Agitator Pump