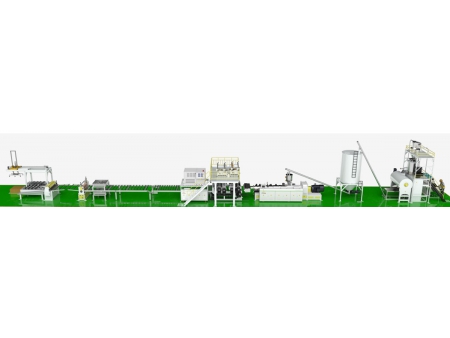

Mixing & Extrusion Equipment for SPC Flooring Production

Stone Plastic Composite (SPC) Flooring Making Machine

The mixing and extrusion equipment for SPC flooring production involves a high speed heater mixer and extrusion equipment.

Desired for its plastic forming capabilities, this mixer is widely used for combining PVC and resin, coloring and integrating polyethylene and polypropylene granules, and also pre-drying wet resin compositions. The mixed raw material is fed into an extruder, forming it into sheets which are hot-pressed with a wear-resistant layer and color film, creating the SPC flooring.

The GRH-1500 high speed heater cooler mixer is a revolutionary development in mixing technology. Drawing on foreign advanced technology as its foundation, this mixer features high-speed paddles that rapidly turn material within its cylinder wall, generating friction heat and aiding electric heating that allows for optimal mixing of materials.

Technical Parameter

| Parameter | Data |

| Output | ≤ 3000 kg/h |

| Total volume | 1500 L |

| Effective volume | 1050 L |

| Mixing time | 10-12 min/ Batch |

An extruder is employed to extrude the base material and the PVC decor film and the wear layer are all pressed together and compounded in one operation, making the process fairly simple and reducing the thermal investment costs. In general, an automated production method is attainable.

Design Parameters

| Parameter | Data |

| Power | 380 V/50 Hz/3P |

| Size | L=975 mm |

| Thickness | δ = 1.0-9.0 mm |

| Linear speed | 1.5-2.4 m/min |

| Production capacity | 22-30 t/24 hrs |

Working Environment Requirements

| Parameter | Data |

| Production capacity | 22-30 t/24 hrs |

| Workshop floor requirement | 10 cm cement floor, bearing capacity >1.5 t/m2 |

| Product dimension | Width 970 mm, thickness 2~8 mm, Max. length 2500 mm |