Railway Windshield

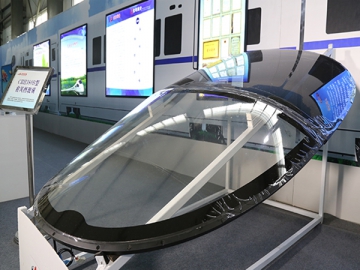

Train Windshield / Commuter Train Window Glass / Railway Glass Windshield

The development of a front windshields for railway vehicles has to take a number of things into consideration in order to guarantee basic requirements for performance and safety, while still maintaining a reasonable cost. These key factors include the impact resistance, age resistance, peripheral protection, low temperature resistance, easy product maintenance (mechanical repair and simplified electrical connections), as well as a resistance to thermal shock and pressure waves.

With more than 30 years in the industry, the development of new railway vehicles presents new challenges and concerns that weren't prevalent 30 years ago, including a clear visibility, a better impact resistance, and more comfortable interior decorations. Because of that, the railway vehicle manufacturers require windows to be resistant to a number of factors, easy to install, inexpensive to maintain, easy to clean and easy to acquire spare parts for the entire system when necessary.

Based on our strong R&D team, cutting edge technology and outstanding technical support from leading grazing research organizations, Jinlong Equipment has developed a new series of front windows to meet different impact requirements as regulated by multiple industry standards. We have hundreds of glazing compositions and construction projects tested each year in integrated testing facilities belonging to both national organizations and third party testing facilities.

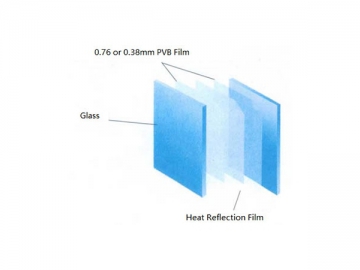

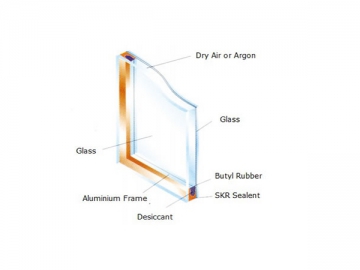

1. Optimal Glazing Structure

The Jinlong Equipment CRH windshield glazing is constructed using multiple layers and interlayer glasses of varying thicknesses. With our extensive knowledge, we are able to define the best interlayer structure for reaching a given impact, fire/smoke resistance, as well as other relevant performance regulations. Thanks to a local R&D panel, as well as technical support from China National Glazing Research Institute, we are capable of evaluating and incorporating glazing front windows into the overall design of the railway vehicle at its earliest development stages, earning us a position at the top of the supplier chain.

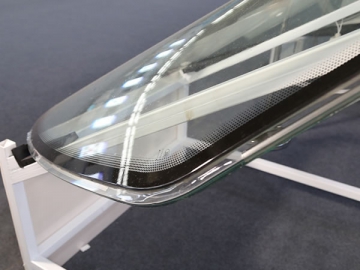

2. Extraordinary Bending Effect

Depending on the shape and specific mechanical requirements, Jinlong Equipment offers a complete set of bending tools, methodologies and processes.

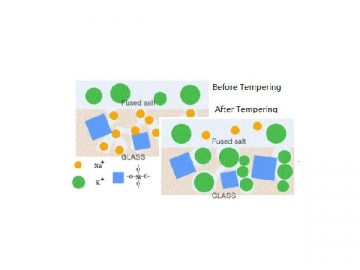

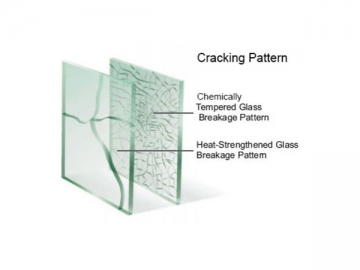

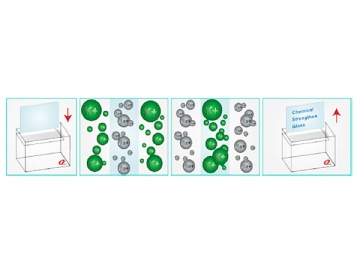

3. Chemical Tempering

In addition to thermal tempered glass, we are able to offer state of the art chemical tempering treatments that significantly increase the impact and pressure resistance attributes for glass. Combined with a unique glass structure, it's an ideal option for long term application.

4. Anti-Spall Protection

To provide the full scale protection to the driver inside the cab, a special membrane called a spollshield is applied to the inner surface of the glass to prevent the projection of spalls and other material into the cabin.

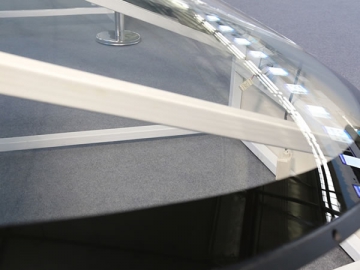

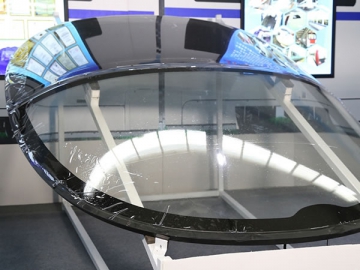

5. Complete Window Set

We are capable of providing customized framing systems which allow for an easy transportation as well as a quick installation. With this framing system, windshields can be optimized in shape and capability of meeting numerous strict requirements as set by the train manufacturer.

Application

1. The windshield complies with the following international requirements: BS EN 15152, BS EN 50125, BS EN 60721-3-5:1997, EN DIN 5510-2:1996, DIN EN 12150-1, ISO 9050-2003, EN 12663-2010.

2. Glazing is done to meet customer requirements at the highest possible speed.

3. The application temperature ranges from -40 to 40°C.

4. The windshield complies with various urban rolling stock standards.

5. Glazing is done to meet special optical performance levels as per customer requirements.

6. The glazing gives the windshield glass a long service life with complete reliability.

Advantages

1. Solutions that satisfy even the most strict standards and requirements of various international agencies

2. State of the art technology targets the highest level of glazing applications.

3. An experienced R&D panel, plus outstanding support from the China National Glazing Research Institute.

4. Friendly and competent after-sales services.

5. Quick installation, disassembly, replacement and part interchangeability.

6. Spare parts available within the product's entire service span.