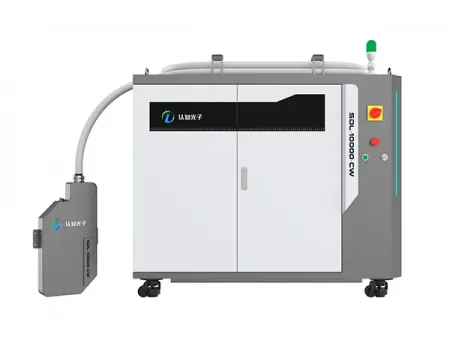

SDL-10000-CW Software Defined Fiber Laser

Laser Welding System Components

Flexible laser welding in metal thicknesses greater than 10mm

SDL-10000-CW software defined fiber laser is a groundbreaking product from CP Laser, engineered to overcome key challenges in the field of laser welding. Based on high-energy laser phased array technology, this software defined laser gives you unparalleled control with a welding spot morphology that is definable, orderable, and switchable, along with a scannable focus. The software defined fiber laser is distinguished by its triple advantages of high power, high beam quality, and high dynamic beam shaping frequency. It delivers a single-fiber laser output of 10kW, a beam quality of 1.2 times the diffraction limit, and a beam shaping frequency of 10MHz.

| Optical Characteristics | |

| Operation mode | CW/Modulated |

| Laser power (kW) | 10 |

| Power tunability (%) | 10-100 |

| Polarization | Linear /Circular /User-defined/ Vector beam |

| Wavelength (nm) | 1064 |

| Beam Quality (M²) | <1.2 |

| Beam shaping frequency(MHz) | 10 |

| Optical Output | |

| Beam output | Free space collimated beam |

| Output diameter (mm) | 25 |

| Fiber length (m) | 10(customizable) |

| Environmental Adaptability | |

| Operating conditions | -5- 45℃,<90%RH,can be reinforced to meet special environments |

| Storage conditions | -20- 45℃,<90%RH,can be reinforced to meet special environments |

| Cooling Requirements | |

| Method | Water-cooling |

| Cooling capacity (kW) | 40 |

| Nominal water flow rate (L/min) | 150 |

| Cooling water temperature range (°C) | 20±1 |

While conventional industrial lasers typically offer only high power, and existing specialized lasers may provide high power and high beam quality, the SDL-10000-CW introduces a third, irreplaceable advantage: high dynamic beam shaping frequency. This feature is a core differentiator for welding steel, aluminum alloys, and die-cast aluminum parts with thicknesses over 10mm. Its dynamic beam shaping frequency is an impressive four orders of magnitude higher than current solutions, enabling it to solve complex welding problems.

The output parameters of the software-defined laser can be freely configured to produce any desired laser shape, providing exceptional flexibility for your specific needs.

- Materials

Ideal for high-reflectivity, high-thermal-strength, and high-melting-point materials such as aluminum alloy, high-temperature alloys, and high-strength steel. It also excels at heterogeneous welding (stacking welding, butt welding, and T-welding) of metals with different thicknesses or materials, as well as thick metal welding (10-20mm high-strength structural steel, aluminum/copper alloys up to 10mm) and for the high-speed welding of extremely thin materials, such as lithium battery electrode materials and fuel cell bipolar plates. - Typical Scenarios

Welding high-strength low-alloy steel pipelines, extending the service life of wind turbine tower welds, high-speed single-pass welding of ship deck steel, and welding aluminum and die-cast aluminum parts for new energy vehicles. Other applications include high-speed welding of motor hairpins and high-speed welding of battery tabs. - Key Advantages

Real-time control of beam shape, high-speed orientation, and spot focus without any moving parts.

Remote, large-focal-length scanning to increase processing range and speed.

A real-time focus correction function that allows a single-mode laser to achieve twice the depth of focus.

Multi-functional Integrated Laser Workstation for Laser Cutting/Welding/Additive Manufacturing

- Typical Scenarios

Integrated additive/subtractive manufacturing equipment, automotive production lines with integrated cutting and welding, and Industry 4.0 flexible production line demonstration projects . It is also perfect for laser material processing R&D and teaching labs and optical field-controlled laser material processing R&D centers. - Main Advantages

High-speed dynamic beam shaping ensures seamless, multi-functional integration.

Closed-loop management of power, beam quality, and spot morphology allows for traceable quality.

A built-in optical field control device provides real-time compensation for thermal distortion.

Dynamic beam shaping ensures processing error compatibility across laser cutting, welding, and additive manufacturing.

High-Energy Laser Phased Array/Coherent Synthesis/Spectral Synthesis

- Typical Scenarios

Coherent synthesis, spectral synthesis, and high-energy phased array lasers. Also suitable for coherent/spectral hybrid synthesis high-energy lasers. - Main Advantages

High spectral brightness: single-fiber single-mode output of 10kW with a linewidth less than 100GHz.

Built-in optical field control devices compensate for distortion in the synthesis optical path.

Achieves efficient coherent/spectral synthesis without the need for an optical axis pointing adjustment mechanism.

Delivers high-efficiency phased array coherent synthesis without the need for sub-aperture beam shaping devices.

Laser Directional Energy/Transmission Systems

- Typical Scenarios

Laser C-UAV, C-RAM, coherent laser radar, air-to-ground laser communication, and remote laser energy transfer charging. - Main Advantages

The built-in MHz frequency optical field control device compensates for atmospheric turbulence and mechanical jitter.

Suppresses speckle and atmospheric scintillation during coherent imaging to improve quality.

Compensates for turbulence in communication to increase bandwidth and lower the bit error rate.

Our engineers are always here for you.