Vacuum Rake Dryer Paraformaldehyde Plant

The vacuum drying process is a traditional production process to produce paraformaldehyde. It is simple and efficient, with minimal loss of formaldehyde and particulate matter.

Helipont promotes the drying process by updating the scraper condensation with the first-efficiency evaporator, which condenses the 50% formaldehyde to 75%. The concentrated formaldehyde then comes into the rake dryers for further dewatering, finally resulting in paraformaldehyde.

The off gas discharged from the rake dryer includes steam and formaldehyde steam. It can be absorbed via condensation absorber tower to produce a diluted formaldehyde solution, which can be reused in the latter process.

- Rake dryers

- Drying absorber tower

- Evaporator

- Separator

- Buffer tank

- Distillation kettle

- Discharging machine

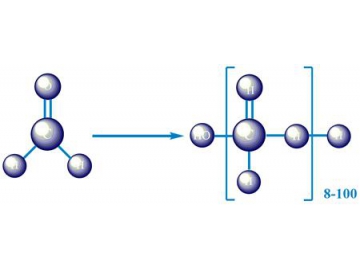

- The theory for first-efficiency evaporator is climbing film evaporation

- The diluted 10-15% formaldehyde solution from the drying process can be reused. It can be used to produce methylal, urotropine or mixed to 37% formaldehyde for sale.

- It is batch form operation. Each batch feed for rake dryer is around 4-5m3, drying time: 4-6 hours.

- Condense the 50-55% formaldehyde solution;

- Drying and further dewatering.

- Treatment of the off gas (including steam and formaldehyde steam).

If you want to know more about the production process in details, please contact us.

| Name | Process Index | Remark |

| Paraformaldehyde content | 93-96%w/w | Normally96% |

| Formic acid | <0.03% | |

| Melting range | 120-170℃ | |

| Ash content | <100ppm | |

| Appearance | White powder | |

| Methanol content | <1wt% | |

| Free water | <1wt% | |

| Iron content | <2ppm |

| Item | Specification | In one company |

| Methanol | Pure99.5% | ≤1280 kg/t(without dilute formaldehyde) |

| Steam | 0.4MPA | ≤2,250 kg/t |

| Electricity | 380V | ≤130 kWh/t |

| Dilute formaldehyde | (19~22%) | -2,200 kg/t |

| Circulating water | 30~38 | 400 m3/h |

Projects Were Work on