Washer Extractor

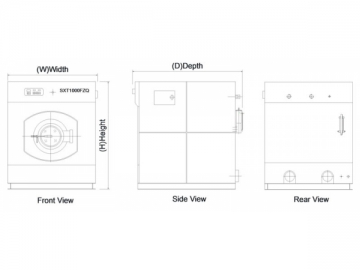

- Front

- Front

- Rear

The washer extractor (100kg) is a multifunctional laundry machine designed with an automatic unloading system, easy operation, high efficiency and energy saving features.

Structure of the Washer Extractor

1. Heavy duty suspension and frame system enhance the washing machine's stability.

2. A uniquely designed inner drum guarantees reliable and consistent washing. The machine is applicable to all kinds of flatwork.

3. Equipped with a standard large LCD display or touch screen controller, this washer extractor has been pre-programmed with over 30 procedures to apply to a wide range of machines and meet customers' different requirements.

4. Self-diagnosis function helps users quickly locate fault points and efficiently solve problems.

5. Its large loading door makes loading and unloading easy.

6. High-speed running is achieved through the use of heavy-duty industrial bearings and water-sealing mechanisms which provide excellent extraction performance.

7. Automatic soap flushing system prevents soap residual on items being washed.

8. The optional automatic soap dispensing device makes this machine a one-key wash, ensuring the commercial washer saves water, time, and energy.

- Heavy Duty Suspension and Frame System

- Automatic Soap Supplying and Dispensing Device (Optional)

- Touch Screen Controller (Optional)

Complete Washing Functions and Energy-Saving Design

1. Adjustable settings for washing time, washing and rinsing frequency, water level and temperature allow the machine to meet the different demands of users and be easy to operate.

2. With a fish-eye design, the inner drum features a smooth surface and stiffness, ensuring high washing cleanliness and with a low wear rate.

3. Effective protection for clothing and flatwork is achieved through an automatic soap dispenser, which dilutes the detergent before it comes into the frequency conversion washer extractor, preventing direct contact between high-concentration chemicals and the materials to be washed.

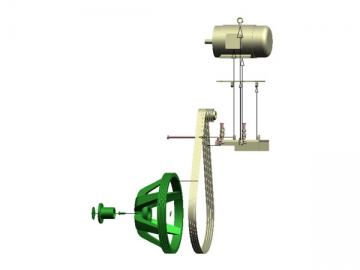

4. We have adopted a VFD (Variable Frequency Drive) system in the design of this industrial washing machine. This unique driving mechanism, facilitated by a specialty frequency conversion motor, provides ideal driving solutions catered to different wash requirements.

5. High extract G factor provides excellent extraction performance, reducing drying and ironing time and extending the flatwork's service life.

- Fish-Eye Design of the Inner Drum

- VFD (Variable Frequency Drive) Driving System

- Inverter and Electrical Cabinet

User-Friendly Design of Washer Extractor

1. Large door provides high washing efficiency and makes the machine ideal for industrial applications.

2. An inching button makes for easy unloading. Tilting device is optional for large capacity models.

3. Emergency button is easy to access in case of any danger.

4. Control panel is designed to help users easily operate the machine.

5. Built-in lubrication system makes maintenance easy.

6. Design with dual-inlets and dual-outlets (optional) promotes washing efficiency.

7. Hot/cold water supply switch (optional) helps the machine adapt to different working conditions.

8. Manual control (optional) is available for emergency washing, saving time.

Automatic Tilting System (Optional)

- Front Tiling for Unloading

- Cylinder of Unloading System

Super Corrosion Resisting Performance of the Washer Extractor

As a major commercial cleaning equipment supplier, LittleDuck uses only quality materials in the production of this automatic washer. High quality S/S304 is adopted to make the inner drum and S/S316 is used for the soap dispenser. All components that are in contact with water are made of corrosion-resistant material, significantly extending the machine's lifespan.

5. Standard Features of the Washer Extractor

1). Programmable computer control with up to 30 wash procedures;

2). Heavy-duty frame and suspension system;

3). Frequency conversion drive system;

4). Industrial bearings and oil seals;

5). High speed extract with 300 G-force;

6). Heating resource: steam or electrical;

7). S/S 304 for all visible sides except for back panel;

8). Large door design for easy loading and unloading;

9). Flushable soap dispensers;

10). Pneumatic valves;

11). Protection devices for over-vibration;

12). Built-in lubrication design;

13). Easy-to-access emergency stop button.

Optional Designs for the Washer Extractor

1. Dual drainage outlets;

2. Integration of both steam heating and electrical heating for SXT1000 and below;

3. Automatic switch between cold water and hot water;

4. Manual control;

5. Automatic soap dispenser;

6. Front tilting device for automatic unloading on capacity 100kg model.

Technical Parameters of the Washer Extractor

| Steam Heating Model | Unit | |||

| Electrical Heating Model | ||||

| Max. Dry Weight Capacity | kg/lbs | 30 / 70 | 50 / 110 | 100 / 220 |

| Drum Diameter | mm | 890 | 1020 | 1200 |

| Drum Depth | mm | 560 | 610 | 885 |

| Drum Volume | Liter | 348 | 500 | 1000 |

| Width | mm | 1310 | 1630 | 1790 |

| Depth | mm | 1465 | 1620 | 1890 |

| Height | mm | 1635 | 1900 | 1900 |

| Washing Speed | RPM | 40 | 37 | 38 |

| Distribution Speed | RPM | 65 | 62 | 65 |

| Low Extract Speed | RPM | 400 | 400 | 400 |

| High Extract Speed | RPM | 800 | 750 | 700 |

| Unloading Speed | RPM | 15 | 15 | 15 |

| G-factor of High Extract | G | 318 | 320 | 328 |

| Work cycle of Standard Mode | Mins | 50 | 50 | 50 |

| Cold Water Inlet | mm, inch | 25, 1" | 40, 1 1 / 2 " | 50, 2" |

| Hot Water Inlet (optional) | mm, inch | 25, 1" | 40, 1 1 / 2 " | 50, 2" |

| Steam Inlet | mm, inch | 25, 1" | 25, 1" | 25, 1" |

| Drain Outside Diameter for sewage | mm | φ76 | φ110 | φ110 |

| Drain Outside Diameter for reuse (optional) | mm | φ76 | φ110 | φ110 |

| Compressed Air | mm | φ8 | φ8 | φ8 |

| Steam pressure | MPa | 0.4~0.6 | 0.4~0.6 | 0.4~0.6 |

| Cold Water pressure | MPa | 0.2~0.3 | 0.2~0.3 | 0.2~0.3 |

| Compressed air pressure | MPa | 0.4~0.6 | 0.4~0.6 | 0.4~0.6 |

| Power Supply | AC | 380V/3Phase/50Hz | 380V/3Phase/50Hz | 380V/3Phase/50Hz |

| Power Line Section (copper wire, at steam heating model) | mm2 | 4 | 4 | 6 |

| Motor Power | kW | 3.2 | 5.5 | 8.5 |

| Inverter Capacity | kW | 3.7 | 7.5 | 11 |

| Water consumption | L/cycle | 580 | 900 | 1800 |

| Steam consumption | kg/cycle | 24 | 30 | 60 |

| Electricity consumption (steam heated model) | kW/cycle | 0.65 | 1.1 | 1.7 |

| Noises | dB | <75 | <75 | <75 |

| Net Weight | kg | 1080 | 1800 | 3000 |

| Option Electrical Heating Model | ||||

| Electrical Heating Power | kW | 18 | 27 | 63 |