101BS Egg Grader (4,000 EGGS/HOUR)

This egg grader is a combination of the 101B egg grader and the 604A accumulator. This egg grading machine sorts eggs into 7 grades by weight, with a grading accuracy of ±1 gram and a production capacity of 4000 eggs per hour. Optional accessories include a manual tray loader or the 602 vacuum egg lifter for easier egg loading. Additionally, the 402H dual-head printer can be installed on the 101B's conveyor rollers for coding functionality.

This egg grader can also be connected to the egg washer to form the egg processing line, achieving a production capacity of 3000 eggs per hour.

| Name | Egg grader |

| Product code | 101BS |

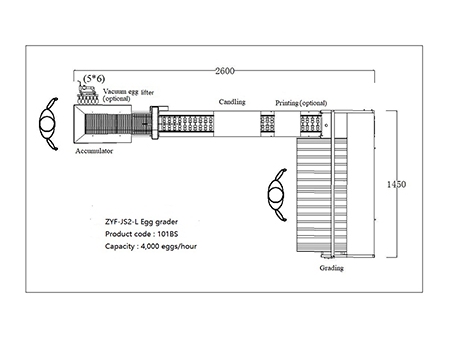

| Model | ZYF-JS2-L |

| Capacity | 4,000 eggs/hour |

| Accuracy | ±1 gram |

| Grade | 7 |

| Power | 308W |

| Voltage | 110/220V, 50/60HZ, single phase |

| Dimension (L*W*H) | 2.6*1.45*1.8 M |

| Net weight | 200KG |

| Gross weight | 300KG |

| Function | Egg accumulating, grading & candling, manual collection table,optional egg printer, vacuum egg lifter or manual tray loader for egg loading |

- Accumulating

- Manual loading/Manual tray loading/Vacuum egg lifting (optional)

- Candling

- Egg printing (optional)

- Grading

- Manual collection table

The Zenyer 604A accumulator is specifically designed to connect with the Zenyer 101A/101B/102A/102B egg graders facilitating egg loading. This accumulator can temporarily store at least 3 trays of eggs (3*30=90 eggs), saving users time during the loading process. It features an adjustable diverter so that when it is connected to the 101A/101B, it can be adjusted to two lanes; and when it is connected to the 102A/102B, it can be adjusted to three lanes.

Manual egg loadingEggs are manually placed on the 604A accumulator.

The optional manual tray loader can be installed on the accumulator, allowing for the loading of 30 eggs at a time onto the accumulator. The operator simply places an egg tray containing 30 eggs (either pulp or plastic trays) onto the manual tray loader. By flipping the manual tray loader, the eggs are gently transferred into the accumulator. The manual tray loader operates without requiring any additional power.

For even greater efficiency and ease of use, an optional vacuum egg lifter can be added to the system. This accessory enhances the egg loading process by allowing the operator to handle 30 eggs at a time with minimal effort. The vacuum egg lifter features a 5x6 suction head that gently lifts the eggs from the tray using negative pressure, ensuring secure handling. Once lifted, the eggs are manually placed onto the accumulator. From there, the eggs are automatically aligned and sorted before being transferred to the feeding roller of the egg grader for further processing.

Using LED light inspection, the eggs are illuminated to allow operators to visually identify and manually remove defective eggs, such as cracked, misshapen, dirty, or black-spotted eggs. The egg candling device is strategically positioned beneath the dual-row rollers of the 101B egg grader. These rollers are equipped with forced rotation bars that continuously rotate the eggs as they pass through, ensuring all sides of the eggs are inspected. Additionally, the inspection units are fitted with a candling hood and mirror, enabling operators to view the backside of the eggs, eliminating blind spots and enhancing the overall effectiveness of the inspection process.

The Zenyer 402H egg printer with 2 print heads is specifically designed for the Zenyer 101A/101B egg graders and can be mounted directly onto the grader's conveyor rollers. When eggs pass under the printer's optical sensor, the printing process is triggered automatically.

This printer can print text, numbers, logos, and dates onto the eggs, providing traceable information about the egg's origin. This traceability enhances consumer confidence by offering reassurance about the quality and safety of the eggs.

The Zenyer 101B egg grader has a production capacity of 4000 eggs per hour and can sort eggs into 7 weight categories with a grading accuracy of ±1 gram.

After grading, the eggs automatically drop into the corresponding lanes on the grader's collection table. The operators then manually place the eggs into the appropriate egg cartons and egg trays.