Bearing Swivel

Wire rope anti-rotation connector

- Working Load Limit 0.75-60t

- Rotation 360 degree

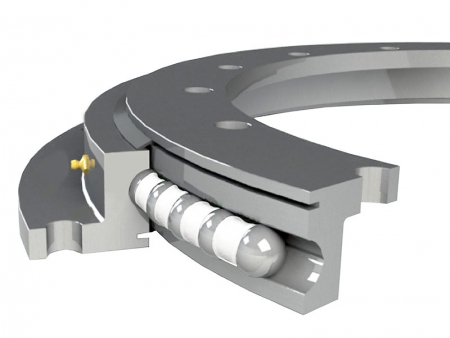

Bearing swivel is a specialized device designed for precisely and reliably lifting and handling loads. It is mounted between the lifting rope and the load to provide free rotation for large cranes and heavy duty lifting equipment that are commonly used in outdoor applications. The bearing swivel is sometimes also known as wire rope anti-rotation connector since it serves as a connector to allow the safe and reliable rotation of loads without rope twisting. Supporting a working load limit of 0.75–60t (customizable up to 200t), it rotates smoothly up to 360° under load while handling high tension and compressive forces. This swivel ensures safe and efficient handling of industrial equipment and materials, making it ideal for heavy-duty lifting in demanding environments.

- Every load-bearing component is stamped with a batch number for traceability; all rotating components undergo 100% magnetic particle inspection

- Independently tested with double the safe working load during certification, and withstands 1.5x load fatigue testing for 20,000 cycles

- Manufactured to meet EN1677-1 production standards, with certified test reports available upon request

- Built-in bearings allow smooth 360° rotation, ensuring high compressive strength and enhanced performance

- Equipped with a grease fitting for easy maintenance and upkeep

- Supports a working load limit of 0.75–60t, with custom options available for load capacities up to 200t

- Features a 4:1 safety factor and undergoes 100% non-destructive testing

- Swivel ring forged from high-strength, high-toughness alloy steel, with precision machining and heat treatment for added durability

- Epoxy resin electrostatic powder coating ensures corrosion resistance and extended service life

| Item No. | Working Load Limit (t) | Dimensions (mm) | Weight (kg) | |||||||

| B | K | L | C | A | D | G | H | |||

| | 0.75 | 34 | 107 | 133 | 13 | 15 | 10 | 6 | 22 | 0.5 |

| | 1.50 | 40 | 119 | 159 | 20 | 18 | 13 | 8 | 26 | 0.9 |

| | 3.00 | 53 | 160 | 210 | 25 | 23 | 19 | 10 | 32 | 2.3 |

| | 5.00 | 67 | 203 | 267 | 32 | 32 | 22 | 14 | 37 | 4.4 |

| | 8.50 | 78 | 250 | 326 | 38 | 40 | 30 | 14 | 54 | 7.6 |

| | 10.00 | 106 | 310 | 410 | 50 | 42 | 38 | 25 | 54 | 19.5 |

| | 15.00 | 119 | 320 | 440 | 60 | 48 | 38 | 25 | 57 | 21.7 |

| | 25.00 | 137 | 405 | 535 | 65 | 62 | 50 | 30 | 70 | 39.5 |

| | 35.00 | 154 | 415 | 545 | 65 | 62 | 50 | 33 | 70 | 46.2 |

| | 60.00 | 270 | 670 | 890 | 110 | 100 | 80 | 75 | 120 | 352.0 |

* Safety factor of 4:1;

| Item No. | Working Load Limit (t) | Dimensions (mm) | Weight (kg) | ||||||

| B | K | L | C | A | D | H | |||

| | 0.75 | 34 | 107 | 131 | 12 | 15 | 10 | 22 | 0.5 |

| | 1.50 | 40 | 119 | 151 | 16 | 18 | 12 | 26 | 0.8 |

| | 3.00 | 53 | 160 | 210 | 25 | 23 | 16 | 32 | 2.0 |

| | 5.00 | 67 | 205 | 267 | 31 | 32 | 22 | 37 | 3.9 |

| | 8.50 | 78 | 246 | 316 | 35 | 37 | 24 | 50 | 6.7 |

| | 10.00 | 106 | 316 | 408 | 46 | 42 | 38 | 53 | 18.6 |

| | 15.00 | 119 | 330 | 426 | 48 | 48 | 38 | 56 | 19.9 |

| | 25.00 | 137 | 403 | 525 | 61 | 62 | 50 | 69 | 36.5 |

| | 35.00 | 154 | 423 | 545 | 61 | 62 | 50 | 69 | 47.6 |

* Safety factor of 4:1;

| Item No. | Working Load Limit (t) | Dimensions (mm) | Weight (kg) | ||||||

| B | K | L | I | T | J | W | |||

| | 0.75 | 34 | 107 | 133 | 13 | 12 | 10.5 | 35 | 0.5 |

| | 1.50 | 40 | 119 | 159 | 20 | 15 | 13.5 | 46 | 0.9 |

| | 3.00 | 53 | 160 | 210 | 25 | 20 | 20.0 | 57 | 2.1 |

| | 5.00 | 67 | 203 | 267 | 32 | 26 | 33.0 | 69 | 4.3 |

| | 8.50 | 78 | 250 | 326 | 38 | 32 | 37.0 | 92 | 7.3 |

| | 10.00 | 106 | 310 | 410 | 50 | 42 | 44.0 | 104 | 17.0 |

| | 15.00 | 119 | 320 | 440 | 60 00 | 49 | 54.0 | 117 | 21.2 |

| | 25.00 | 137 | 405 | 545 | 70 | 60 | 66.0 | 140 | 39.0 |

| | 35.00 | 154 | 415 | 555 | 70 | 60 | 66.0 | 140 | 45.8 |

| | 60.00 | 270 | 670 | 890 | 110 | 75 | 80.0 | 230 | 253.0 |

* Safety factor of 4:1;

| Item No. | Working Load Limit (t) | Dimensions (mm) | Weight (kg) | ||||||||||

| B | K | L | A | G | D | H | T | J | W | I | |||

| | 0.75 | 34 | 107 | 133 | 15 | 6 | 10 | 22 | 12 | 10.5 | 25 | 13 | 0.5 |

| | 1.50 | 40 | 119 | 159 | 18 | 8 | 13 | 26 | 15 | 13.5 | 46 | 20 | 0.9 |

| | 3.00 | 53 | 160 | 210 | 23 | 10 | 10 2 | 32 | 20 | 20.0 | 57 | 25 | 2.2 |

| | 5.00 | 67 | 203 | 267 | 32 | 14 | 22 | 37 | 26 | 33.0 | 69 | 32 | 4.4 |

| | 8.50 | 78 | 250 | 326 | 40 | 14 | 30 | 54 | 32 | 37.0 | 92 | 38 | 7.4 |

| | 10.00 | 106 | 310 | 410 | 42 | 25 | 38 | 54 | 42 | 44.0 | 104 | 50 | 18.0 |

| | 15.00 | 119 | 320 | 440 | 48 | 25 | 38 | 57 | 49 | 54.0 | 117 | 60 | 21.2 |

| | 25.00 | 137 | 405 | 540 | 62 | 30 | 50 | 70 | 60 | 66.0 | 140 | 70 | 40.0 |

| | 35.00 | 154 | 415 | 550 | 62 | 33 | 50 | 70 | 60 | 66.0 | 140 | 70 | 46.7 |

| | 60.00 | 270 | 670 | 890 | 100 | 75 | 80 | 120 | 75 | 80.0 | 230 | 110 | 302.0 |

* Safety factor of 4:1;