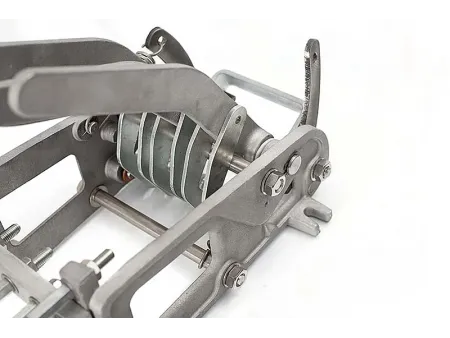

Emergency Valve Operator

Tank Truck Valve Operators

Mechanical operator utilizes lever action to open and close emergency valves on tank trucks

- Number of operator handles: 1-6

- Cable diameter: 3mm

- Accessories material: 304 stainless steel

- Frame material: Aluminum alloy

- Installation: Bolts

The emergency valve mechanical operator is a manual lever system installed on fuel tankers to open and close emergency shut-off valves (bottom valves) via steel cable linkage. Each lever controls one valve, and the number of levers can be customized according to vehicle configuration and compartment layout.

Our mechanical operator uses a centralized control structure, routed beneath the tanker, with up to six steel cables extending to the shut-off valves of individual compartments. In case of emergency, operators can manually or remotely activate the handle to immediately close the valve and stop fuel flow. The system features stainless steel components and a cast aluminum body to ensure strength, corrosion resistance, and long-term operational safety.

- Lever and housing are made of cast aluminum alloy, combining lightweight structure with high durability

- Uses a flat-linkage mechanism for compact design and smooth operation

- Equipped with a high-temperature fuse for automatic emergency shut-off

- Integrated cam system with spring return ensures secure valve closure

- Ergonomic bent-handle design allows for quick return via linkage, improving operating efficiency