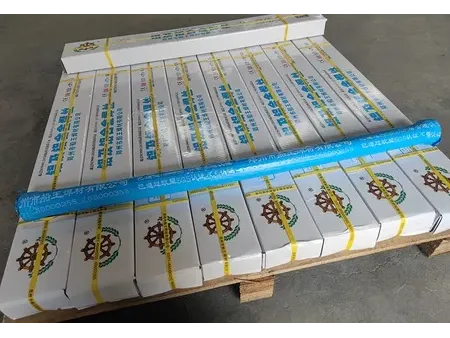

Welding Consumables

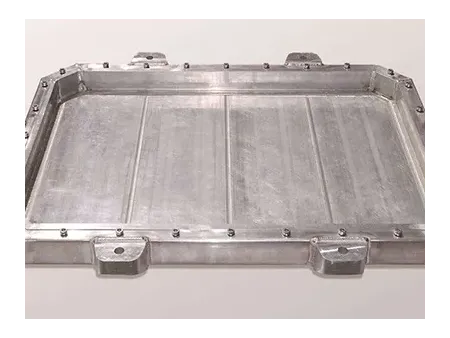

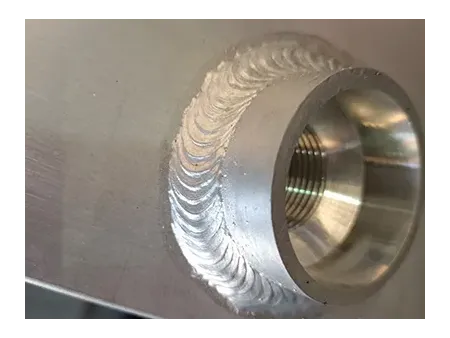

Aluminium-magnesium filler metal for high strength welding of aluminium alloys

- Chemical Designation: AlMg5Cr(A)

- Standard: AWS A5.10, GB/T10858-2023

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | AL | Be | Others | |

| Each | Total | ||||||||||

| ≤0.25 | ≤0.40 | ≤0.10 | 0.05-0.20 | 4.5-5.5 | 0.05-0.20 | ≤0.10 | 0.06-0.20 | Rest | ≤0.0003 | ≤0.05 | ≤0.15 |

For best welding performance, ER 5356 is typically used with AC current and pure argon shielding gas. It can be applied in both MIG and TIG welding. To ensure stable arc performance and high-quality welds, always clean the area to be weld thoroughly and make sure both the base material and welding wire are dry and free of contaminants.