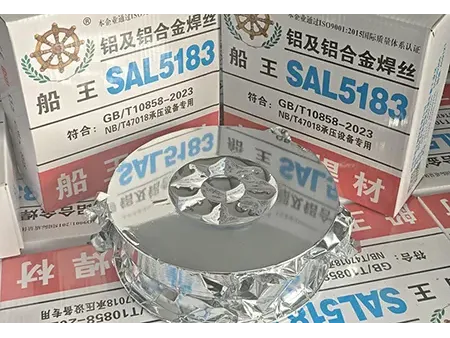

ER 5183 (AlMg4.5Mn0.7(A)) Aluminium Welding Wire

Request a Quote

Welding Consumables

Aluminium-magnesium filler metal for MIG and TIG welding of aluminium alloys where high tensile strength is required

- Chemical Designation: AlMg4.5Mn0.7(A)

- Standard: AWS A5.10, GB/T10858-2023

Chemical Composition (%)

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | AL | Be | Others | |

| Each | Total | ||||||||||

| ≤0.40 | ≤0.40 | ≤0.10 | 0.50-1.0 | 4.3-5.2 | 0.05-0.25 | ≤0.25 | ≤0.15 | Rest | ≤0.0003 | ≤0.05 | ≤0.15 |

Mechanical Properties

- Tensile Strength (MPa): ≥275

- Yield Strength (MPa): ≥130

- Elongation (%): ≥18

Available Sizes

- Welding wire: 1.0/1.2/1.6/2.0/2.4/3.0/3.2/4.0/5.0/6.0mm

- Spool: D300 (9kg), D270 (7kg)

Features

- Contains nearly 5% magnesium and a higher manganese content, which is ideal for welding aluminium alloys that require elevated tensile strength, typically 276 MPa or above

- Offers excellent resistance to seawater corrosion and performs reliably in low-temperature environments

- After anodizing, the weld appears white, providing a clean and uniform color match across the welding area

Applications

- Shipbuilding and offshore drilling equipment

- Railway and automotive components

- Storage tanks and pressure vessels

Packaging

- MIG wire diameter: 0.8mm, 1.0mm, 1.2mm, 1.6mm, 2.0mm

- Package: D300 (9kg/spool), D270 (7kg/spool)

- MIG wire diameter: 1.2mm, 1.6mm

- Package: drum D660 (100kg/drum)

- TIG wire diameter: 2.0mm, 2.4mm, 3.0mm, 3.2mm, 4.0mm, 5.0mm, 6.0mm

- Package: 1000mm length (10kg/box)

- Welding wire diameter: 2.0mm, 3.0mm, 4.0mm, 5.0mm

- Coil inner diameter: D450mm, D300mm

- Package: 10-17kg/coil

Recommended Welding Method

MIG and TIG welding are both suitable options for this type of welding wire, especially when used with alternating current and pure argon as shielding gas. Make sure to clean the joint area thoroughly and keep the welding wire and base metal dry to maintain weld integrity.