Your trusted partner for bagging and palletizing systems

Request a Quote

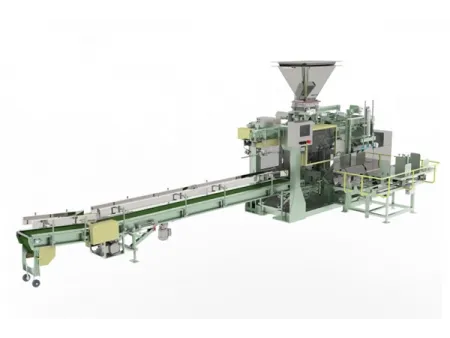

3CM-P

Fully automatic open-mouth bagger for filling granular and powder products into pre-made open-mouth bags

The automatic open-mouth bagging machine is designed for flexible, steady, and continuous operation in bulk-material packaging lines. It handles a wide range of bag types, including paper bags, PE heavy-film bags, and laminated woven bags. The system supports flat-top bags, M-fold bags, and envelope-type bags within a 20–50 kg filling range. With an output of 500–800 bags per hour, it is a practical solution for chemical plants, feed mills, grain processors, and other operations that require consistent and dependable bag handling.

- 3CM-PS Automatic Open-Mouth Bagging Machine (500-800 bags/hr)

- 3CM-PE Automatic Open-Mouth Bagging Machine (500-800 bags/hr)

- 3CM-P Automatic Open-Mouth Bagging Machine (500-800 bags/hr)

Technical Specifications

| Machine dimensions (L×W×H) | 3350×2560×2700mm (excluding upright bag conveyor and weighing scale) |

| Applicable bag materials | Paper–plastic composite bags, heavy-duty PE film bags, laminated woven bags, aluminum foil bags |

| Applicable bag styles | Flat-top bags, M-gusset, envelope-style bags |

| Optional closing methods | Flexible configuration (e.g., sewing heat-seal tape; inner heat sealing folding sewing) |

| Applicable bag size | Length 700–900 mm Width 450–550 mm |

| Bag magazine capacity | 300bags |

| Filling range | 20-50kg/bag |

| Capacity | 500–800bags/hr (depending on material flow and bulk density) |

| Power supply | AC 220V/380V ±5%, 50 Hz±1%, three-phase four-wire |

| Peak power | 25kW |

| Air supply | 0.5–0.7MPa, 145Nm³/hr, inlet pipe diameter 1inch |

| Operating temperature | –5°C to 40°C, dew point –40°C |

| Vacuum system | Integrated rotary-vane vacuum pump |

Specifications are subject to change without prior notice.

Product images may differ from the actual model configuration.

Features

- Handles 20–50 kg bags at 500–800 bags/hr: Supports medium to high-throughput operations while maintaining stable filling performance.

- High-efficiency automatic bag presentation: The auto-bag magazine and pick-up system are built for smooth, continuous operation in busy production environments.

- Independent control and protection for each functional unit: Every module includes coordinated control and safety mechanisms to maintain steady, uninterrupted workflow.

- Motor-driven actuation for improved operating efficiency: Servo-based movement delivers cleaner bag transfer, more precise positioning, and better overall consistency.

- Recommended pairing with KS-series heat sealing systems: Combining the 3CM-P with a KS heat sealer enhances the appearance of the sealed bag and helps prevent leakage and air ingress.

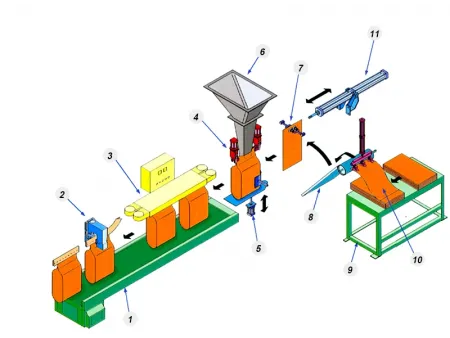

Process Flow Diagram

- 1 Upright bag conveyor

- 2 Bag sewing machine

- 3 Heat sealer

- 4 Filling system

- 5 Bag-bottom flattening device

- 6 Discharge spout

- 7 Empty-bag pick-up unit

- 8 Bag positioning unit

- 9 Automatic bag magazine & dispenser

- 10 Packaging bags

- 11Lateral drive cylinder