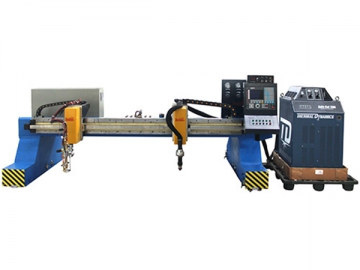

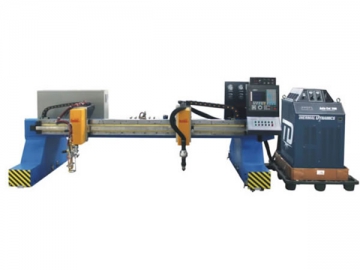

CNC Multi Head Flame Cutting Machine

Constructed with gantry structure, the CNC multi head flame cutting machine is driven by single side or double side. It's the high efficient and high performance automation thermal cutting equipment, combining oxygen gas cutting with computer control and precision mechanism. The CNC oxygen gas cutting torch can cut the plate with any shape.

Technical Parameters| Lateral Rail Guage | 3000-1000mm |

| Effective Cutting Width | 2200-920mm |

| Effective Cutting Length | Length of Guide Rail - 2500mm |

| Cutting Speed | 50-1000mm /min |

| No-load Speed | ≤6000mm /min |

| Cutting Depth | 6-200mm |

| Min. Distance of Cutting Torch(CNC) | 230mm |

| Min. Distance of Cutting Torch(Strip) | 80mm |

| Cutting Thickness of Plate | 6-70mm(Single Gun 100mm) |

| Cutting Gas | Oxygen, Propane or Ethyne(The user can appoint the actual cutting gas according to needs.) |

Structure and Operation Description of CNC Multi Head Flame Cutting Machine

The CNC multi head flame cutting machine consists of gantry frame, longitudinal main and auxiliary guide rail, lateral flame oxygen gas cutting torch, longitudinal strip oxygen gas cutting torch and CNC system. Welded with box-type girder structure and processed with stress relieving after welding, the driving end beam and crossbeam feature compacted structure and nice appearance. The main driving end beam of the equipment adopts Japanese Panasonic ac servo drive and motor to drive Japanese Shimpo speed reducer. Then the longitudinal movement is achieved through the transmission of gear and rack. A horizontal orientated wheel is equipped at the side of driving end beam. The user can adjust the eccentric shaft to make the orientated wheel press on the guide rail tightly to assure the stability and precision of the CNC multi head flame cutting machine in the whole movement. Made of high strength rail, longitudinal guide rail is processed with precision machining on all contact surfaces. At the outside of the longitudinal guide rail is rack processed with precision grinding. The guide rail is fixed through the joining of press plate and backing plate with connection sleeve. This kind of installation can guarantee the longitudinal straightness and parallelism of the guide rail. The lateral oxygen gas cutting torch is installed on the lateral supporting plate. Through taking usage of Japanese Panasonic ac servo drive and motor to drive Japanese Shimpo speed reducer, the movement of cutting torch is realized via the transmission of gear and rack.

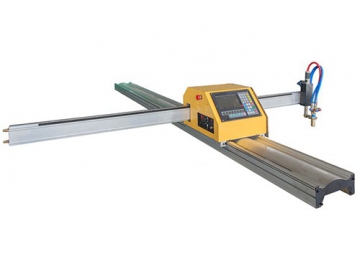

We are an experienced CNC multi head flame cutting machine manufacturer and supplier in China. We provide various types of products such as fiber laser cutter, high speed arc spray equipment, CNC plasma beveling machine, and four roller rolling machine.