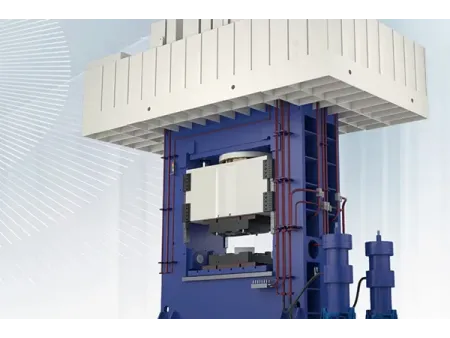

4000 Ton CNC Tube Hydroforming Press

Automatic high-pressure hydraulic hydroforming equipment for the production of automotive components and other industrial metal tubular parts

These 4000-ton CNC tube hydroforming presses are used for manufacturing lightweight, high-strength tubular structural parts, mainly for automotive and industrial applications. Their design focuses on meeting current production demands for weight reduction, improved part quality, and higher efficiency. As tube hydroforming moves toward larger, more flexible, and more automated production lines, precise ultra-high-pressure control and servo-hydraulic systems play a key role in overall performance. The main features of CNC tube hydroforming presses include the following:

- Ultra-high-pressure capability

Each hydroforming press is equipped with two intensifier cylinders, which allows internal pressure to reach up to 400 MPa. This pressure level allows tube hydroforming presses to handle complex parts with large deformation and high yield strength. - Accurate pressure control

Pressure control at the intensifier cylinders is maintained within ±0.5 MPa, meeting the precision requirements for tube hydroforming processes. - Micron-level displacement control

The cylinder displacement sensors can detect movement with a resolution down to 0.001 mm. During operation, the actual positioning accuracy of the side cylinders is controlled within ±0.1 mm, supporting precise material feeding during forming. - Efficient servo-hydraulic control

Each hydraulic cylinder is driven by an independent servo control system, with speeds reaching up to 110 mm/s. Compared with conventional servo-valve control, servo-hydraulic control reacts faster and delivers better efficiency while keeping costs at a similar level.

| Item | Unit | Value / Spec | Remarks | |

| Nominal force | KN | 40000 | ||

| Return force | KN | ≥1600 | ||

| Hydraulic system pressure | MPa | 25 | ||

| Side cylinder force | KN | 2500×4 | Two cylinders per side (left & right) | |

| Main cylinder stroke | mm | 600 | ||

| Side cylinder stroke | mm | 180 | ||

| Max. daylight opening | mm | 1350 | ||

| Main cylinder pressing & side cylinder slow-feed control accuracy | mm | ±0.05 | Displacement resolution: 0.01 mm; accuracy ensured by the user control program | |

| Side cylinder center distance | mm | 830 | ||

| Main motor power | KW | 2×75 / 4×63.5 | Dual gear pumps; servo motors | |

| Effective working table size | Left to right | mm | 2700 | Distance between left and right side cylinder faces: 2700 |

| Front to back | mm | 1800 | ||

| Die closing speed | Fast approach | mm/s | approx. 300 | No load |

| Slow approach | mm/s | 28 | No load; 15 mm stroke | |

| Pressing speed | mm/s | 14 | During die closing | |

| Return speed | mm/s | approx. 220 | ||

| Side cylinder speed | Fast approach | mm/s | 100 | No load |

| Slow approach | mm/s | 29 | Under load: 25 MPa; 80 mm stroke | |

| Return speed | mm/s | 90 | No load | |

| Intensifier cylinder speed | Fast approach | mm/s | 49 | No load |

| Slow approach | mm/s | 30 | Under load: 25 MPa; 400 mm stroke | |

Energy Consumption

Servo motor drives are used across the CNC hydroforming press, resulting in lower power consumption and reduced operating noise

Cost Efficiency

Unmanned production with integrated processing steps improves material utilization and helps control overall production costs

Production Efficiency

The hydroforming press uses a dual-die setup, producing two parts per cycle to increase output efficiency

Intelligent Control

A servo control system based on the Beckhoff EtherCAT bus is used, providing fast communication and efficient data processing throughout the production process

Precision Control

A high-precision servo-hydraulic system is applied, with control accuracy maintained within ±0.1 mm to support stable and consistent forming results

- Material feeding accuracy

Feeding displacement accuracy: 0.01 mm

Forming stroke accuracy: 0.02 mm - Internal pressure control accuracy

Synchronization time difference between internal pressure and material feeding: 0.002 s - In-die punching accuracy

Response time between punching, pressure, and feeding axes: 0.002 s

Hole diameter accuracy: ≤ 0.2 mm

Hole position accuracy: ≤ 0.4 mm - Forming accuracy of finished parts

Profile tolerance: ≤ 0.4 mm

Wall thinning rate: < 15%