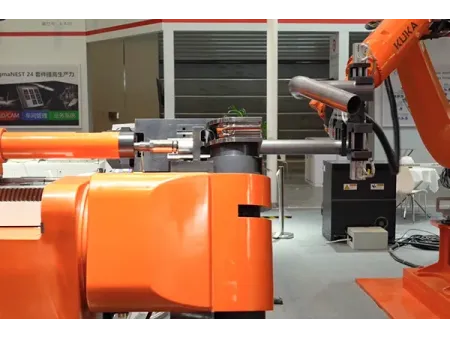

Multi-Axis CNC Tube Bending Machine

High speed pipe bender for metal tubes used in automotive, aerospace and industrial sectors, covering tube diameters from 30mm to 100mm

These multi-axis CNC tube bending machines are designed for precise left- and right-side bending and can be used in automated production setups. They allow short straight ends after the final bend, kept below 1.2D, which helps reduce material usage and overall production costs.

Multi-axis coordinated operation supports high production efficiency and allows dual-head configurations with up to eight tooling stacks, combined with automatic process simulation. A full-servo drive system, together with high-precision transmission components, ensures repeat positioning accuracy of up to 0.02 mm.

- Angle: 13-axis full-servo bending ensures accurate control at any bending angle, with angular accuracy within 0.05° and feeding accuracy up to 0.05 mm.

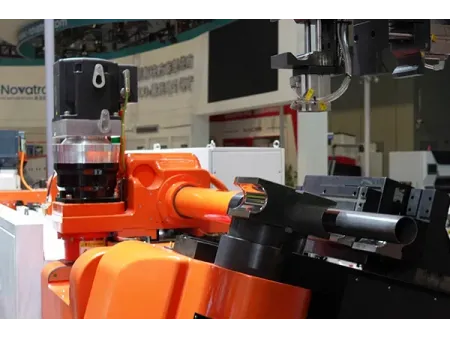

- Circularity: Multi-core mandrel bending combined with synchronized lubrication helps maintain stable tube roundness during the bending process.

- Thinning: Wall thinning is managed by coordinating the bending motion with auxiliary pushing and mandrel movement. Push-feed compensation and synchronized lubrication help keep wall thickness more consistent and improve forming stability.

- Forming: Three-dimensional bending accuracy is controlled within ±0.5 mm, ensuring consistent tube geometry and dimensional stability.

- SUH409L

φ55x1.5mm R=0.8D - SUS441

φ60x1.5mm R=1.2D - SUS441

φ28.6x1.5mm R=1.4D - Aluminum Rectangular Tube

40*45*4mm R=100mm - HR420LA

φ100x2.6mm R=1.5D - SUS409L

φ50x1.5mn R=2D

- Fully servo-driven electric control system without hydraulics, supporting efficient operation, low energy consumption, and low noise levels

- Online simulation automatically calculates the best bending path and helps avoid interference during processing

- Automatic weld seam detection, with optional loading and unloading for unmanned operation

- Left- and right-side dual-head bending with fixed or variable radii, allowing bending in flat, side, inclined, and complex spatial directions

- Scrap discharge function that helps reduce material waste and improve material utilization

- Servo motors equipped with high-precision absolute encoders allow operation to resume after power restart without re-homing

- EtherCAT bus system for fast data transmission, simplified wiring, and a cleaner control layout

- Simple and efficient programming by inputting XYZ coordinates and tooling parameters, with full graphical simulation of the bending process

- Servo-controlled clamping force with automatic detection, ensuring high accuracy, repeatability, and reliable operation

- Lubrication system for pressure die and mandrel components, which helps extend the service life of wear parts

- Intelligent control functions including process simulation, weld seam recognition, clamping force monitoring, real-time operation monitoring, and automatic lubrication

| Weight (including control console) | Dimensions (L × W × H) | Color | Tube diameter range | Max. bending radius (excluding stack bending) | Max. tube loop length | Max. feeding speed | Max. bending speed | Max. tube rotation speed |

| 9000 kg | 4600 × 2400 × 2000 mm | Black and white (textured paint finish) | 30–100 mm | 200 mm | 2300 mm | 700 mm/s | 70°/s | 300°/s |

| Max. head travel speed | Max. head rotation speed | Max. assist push speed | Max. scrap pushing speed | Repeat positioning accuracy | Max. bending output torque | ||||||

| 730 mm/s | 100°/s | 160 mm/s | 160 mm/s | Feeding ±0.03 mm Head linear movement ±0.03 mm Assist push ±0.02 mm Scrap push ±0.02 mm Bending angle ±0.03° Head rotation ±0.03° Tube rotation ±0.03° | 20,000 N·m | ||||||

| Max. feeding force | Max. mandrel extraction force | Max. main clamping force | Max. auxiliary clamping force | Max. assist push force | Max. scrap pushing force | Max. bending angle | Feeding stroke |

| 80 kN | 80 kN | 250 kN | 200 kN | 60 kN | 60 kN | 180° | 2050 mm |

| Head travel stroke | Mandrel stroke | Assist push stroke | Scrap pushing stroke | Main clamping stroke | Auxiliary clamping stroke | Total motor power |

| 1150 mm | 300 mm | 150 mm | 230 mm | 170 mm | 170 mm | 65 kW |

CNC tube bending machines include a bending arm, tube rotation unit, auxiliary push and support arms, tube support system, rotating bending head, head travel unit, mandrel extraction system, tube feeding carriage, tube clamping system, scrap push-out unit, and an integrated control system.

Software Operating System

The control system is developed on a Windows-based platform and includes functions such as process simulation, automatic weld seam detection, clamping force monitoring, automatic loading and unloading, automatic lubrication, abnormal alarms, real-time operation monitoring, and remote support.

Drive Components

The drive system uses high-precision ball screws, low-backlash gear reducers, and high-precision linear guide rails to ensure accurate and stable motion during operation.

Virtual Simulation

Online simulation calculates the optimal bending path in advance and helps avoid interference during the bending process.

Beckhoff Control System

Beckhoff control system, including an industrial control computer, drives, and servo motors.

Other Hardware

Cable carrier and drag chain cables from Igus, Schneider low-voltage electrical components, and a sealed, air-conditioned electrical cabinet.

Our high-speed multi-axis tube bending machines are used for 3D bending of carbon steel, stainless steel, copper, and aluminum alloy tubes across industries such as automotive manufacturing, aerospace, medical equipment, petrochemical, and household applications.

Automotive manufacturing, mainly for chassis components, motorcycle frames, and exhaust systems

Mechanical and industrial manufacturing, including metal piping, hydraulic systems, pneumatic systems, and air-conditioning pipelines

Used in aerospace, petrochemical, medical equipment, and household manufacturing applications