GH018-A Automatic High Speed Sewing Thread Winding Machine

GH018-A Automatic High Speed Sewing Thread Winding Machine

- Sewing thread cones

for a conical package shape with 3" - 4" traverse length

- Tuck- inTuck- in

tuck with the yarn tail in the thread

- STSewing yarn

Sewing yarns are especially made to pass rapidly through a sewing machine. They are a fine cord of a fibrous material, which are made of two or more filaments twisted together. The yarns form efficient stitches without breaking or becoming distorted.

- Spun yarnStaple spun yarn

Textile yarn spun twisted from staple length fiber, either natural or synthetic.

- COCotton

Natural fibre from the cotton plant which is spun into fine yarn.

- PET / PESPolyester

Synthetic fiber made from a thermoplastic polymer that contains the ester functional group in their main chain. Most commonly refers to a type called polyethylene terephthalate (PET) or polyethylene succinate (PES) with a melting point from 103 - 106°C.

- CVViscose

Viscose, formerly known as viscose rayon, is made by treating cellulose with caustic alkali solution and carbon disulphide. It is a soft fibre commonly used in dresses, linings, shirts, shorts, coats, jackets, and other outerwear.

- TYTechnical Yarns

The yarns are used for technical textile products, which are manufactured for non-aesthetic purposes. The function such as rigidity, strength, dimension stability, design flexibility and economic viability is main feature.

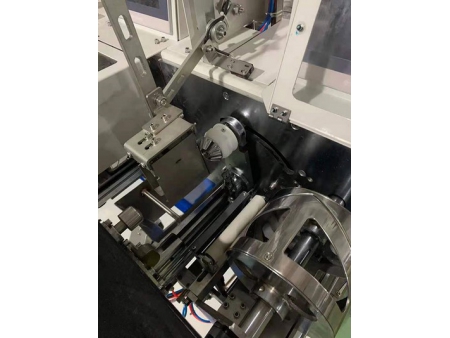

GH018-A fully automatic high speed sewing thread winding machine is applicable to the winding of embroidery threads, sewing threads and so on into 2-4 inches cones.

This sewing thread winder features automatic bobbin feeding and winding system, a computer-controlled automatic yarn length counter, frequency control, a slotted spool yarn guide device, and a pump-based cycling-type oiling device. Thus, the machine offers good shape formation, high efficiency, easy operation, assured safety and reliability, and wide applicability.

| Model | GH018-A auto |

| Take-up tube | Conic shape |

| Spindle number | 4 |

| Drive | Individual motor per spindle |

| Control | Computer controlled |

| Traverse length | 2”-4” |

| Spindle speed | 10000rpm |

| Mechanical speed | 200~1000 m/min |

| Weight | 500kg |

| Installed power | 1.2kW |

| Air pressure | 2 KGS |

| Take-up package diameter | Φ140mm |

| Power supply | 220V (single phase) or 380 V (three phases), 1.2kW |

| Frequency | 50/60Hz |

| Compressed air | 0.3MPa |

| Dimension | 1800×760×1840mm |

- Automatic bobbin feeding and automatic winding system offer high automation.

- Automatic bobbin feeding and no bobbin auto-stop

- Non-contact broken yarn detector is sensitive.

- Automatic bobbin changing is fast and stable, greatly reducing labor cost.

- Computer-based yarn length automatic measuring system comes with an accuracy of ±0.5%.

- Automatic control of winding linear speed is flexibly set within 100-1000 m/min.

- Grooved drum yarn guide system offers fast speed and low noise.

- Grooved drum is manufactured with special material and is polished, being smooth and wear-resistant and having no damage to the yarn.

- Pump-based cycling-type oiling device allows for the setting of oil wheel speed ratio, ensuring uniform oiling combined with the constant linear speed. Each oil wheel is configured with a filter to prevent oil spray and oil waste.

- High productivity: each machine offers an output of 5 kg yarns per hour, and the daily output is up to 110kg based on 22 working hours. The efficiency is 5-6 times higher than that of traditional winding machines.