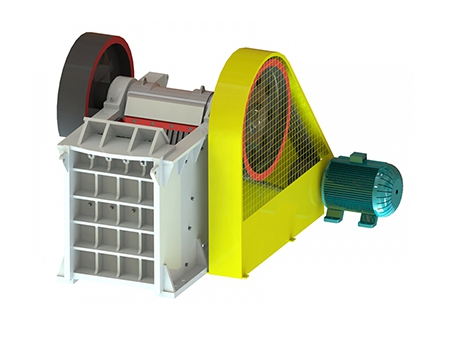

Jaw Crusher, PE Series

Stone Crushing Machine, Aggregate Crushing Machine, Jaw Crushing Plant, Rock Crushing Machine

PE series jaw crusher is generally used as a primary crusher in stone production line, ore production line, and artificial sand production line, etc. It utilizes the movement of the movable jaw and the fixed jaw to reduce large stone materials into smaller parts.

Features of the jaw crusher

1. Ultra-high stability

For this kind of jaw crusher, we utilize steel castings for the movable jaw and forging stock for the eccentric shaft to realize a high stability

2. Large bearing capacity

Comparing with other crusher of the same specification, this stone crusher is equipped with larger and more durable bearings for large bearing capacity

3. Easy operation & convenient maintenance

Besides improving the performance of the jaw crusher, we have simplified its structure to make it easy to be operated and maintained

Working principle of the crushing machine

PE series jaw crusher is motor driven. With the pulley, the V-belt and the Geneva gear driving the eccentric shaft, the movable jaw will perform reciprocating motion along a predetermined trajectory and crush the materials, which are fed into the copper enclosed by fixed jaw, movable jaw and edge guard. Finally, the crushed materials will be discharged through the lower opening.

Applications of the stone crushing machine

Dongmeng jaw crusher has found wide applications in crushing all kinds of ores and large-sized materials in mining, metallurgy, construction, roads, railways, water conservancy and chemical industries.

| Model | Dimension of the inlet (mm×mm) | Max feeding diameter (mm) | Processing capacity (t/h) | Rotating speed of the eccentric shaft (r/min) | Motor power (kW) | Adjustment range of the discharge opening (mm) | Weight (t) |

| PE-250×400 | 250×400 | 210 | 5-20 | 300 | 15 | 20-60 | 2.8 |

| PE-400×600 | 400×600 | 340 | 16-65 | 275 | 30 | 40-100 | 6.5 |

| PE-500×750 | 500×750 | 425 | 45-100 | 275 | 55 | 50-100 | 10.1 |

| PE-600×900 | 600×900 | 500 | 50-120 | 250 | 55-75 | 65-160 | 15.5 |

| PE-750×1060 | 750×1060 | 630 | 52-180 | 250 | 110 | 80-140 | 28 |

| PE-800×1060 | 800×1060 | 650 | 85-143 | 250 | 110 | 100-200 | 30 |

| PE-870×1060 | 870×1060 | 670 | 181-210 | 250 | 110 | 200-260 | 30.5 |

| PE-900×1200 | 900×1200 | 750 | 140-260 | 200 | 110 | 95-165 | 50 |

| PE-1000×1200 | 1000×1200 | 850 | 160-300 | 200 | 110 | 195-265 | 51 |

| PE-1200×1500 | 1200×1500 | 1020 | 300-600 | 180 | 160 | 150-300 | 100.9 |

| PEX-250×750 | 250×750 | 210 | 8-22 | 330 | 22 | 25-60 | 4.9 |

| PEX-250×1000 | 250×1000 | 210 | 16-52 | 330 | 30-37 | 25-60 | 6.5 |

| PEX-250×1200 | 250×1200 | 210 | 20-60 | 330 | 37 | 25-60 | 7.7 |

| PEX-300×1300 | 300×1300 | 250 | 20-90 | 330 | 55 | 20-90 | 11 |