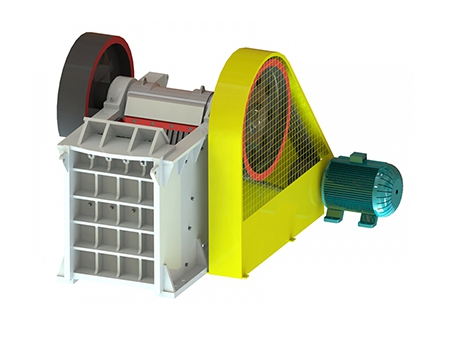

Jaw Crusher, PEW Series

Jaw Crushing Plant, Stone Crushing Machine, Rock Crushing Equipment, Concrete Crusher

PEW series jaw crusher is an ideal choice for processing high-hardness and wear-resistant materials. It is designed aiming at the stone crushing uses for highway, road, railway, airport runway, and other road construction fields.

Features of the crusher

1. Unique design & high production capacity

The adoption of large centrifugal force and high frequency enables a large effective stroke at the bottom of the copper. This jaw crushing machine is able to produce fine-crushed materials supported by the small discharge opening.

2. Convenient adjustment for the discharge opening

This jaw crusher adopts wedge adjustment device for the discharge opening to let it being adjusted to a predetermined value within a few minutes. Accompanied with the hydraulic system, the adjustment process will be done automatically. The system is more convenient, efficient and safe comparing with traditional discharging system that utilizes gasket to realize an adjustment.

3. Stable structure & long service life

To enhance the stability of the system, the bearing saddle of this jaw crusher is integrally welded from steel. The stone crusher employs spherical roller bearings which are large and more durable than common bearings adopted by other crushers. With high bearing capacity and labyrinth seal way, the life of bearings is largely extended.

4. High reliability & durability

The movable jaw assembly is made of high-quality cast steel piece. Forging blank is adopted for the heavy eccentric shaft to make the jaw crusher more reliable and endurable

5. High strength & integral structure of the bearing saddle

We adopt integral cast steel structure for the bearing saddle to realize a good cooperation with the crushing stander, enhancing the radial strength of bearing saddle greatly.

6. High strength

The adoption of finite element analysis technology ensures much higher strength of the stone crushing machine.

7. High output

The latest tooth-shaped guard plate is adopted to increase the effective length of the jaw plate thus improving the output correspondingly

Working principles of the jaw crusher

Dirven by motor, the belt and belt pulley will motivate the movable jaw to move back and forth via the eccentric shaft. The materials will be crushed when the movable jaw moves forward the fixed jaw. As the jaw turns back under the pressure of the eccentric shaft and the spring, the crushed materials will be discharged through the opening. The cyclical running of the motor and the movable jaw helps to realize a mass production process.

Applications of PEW series jaw crusher

Dongmeng jaw crusher is widely applied in the stone crushing process of ore processing, construction aggregate production line, water resources and hydropower engineering, highway, railway, bridges, and other fields.

| Model | Max feeding size (mm) | Rotating speed (mm) | Motor power (kW) | Production capacity (TPH) Closed-side setting (mm) | |||||||||

| 50 | 70 | 80 | 100 | 125 | 150 | 200 | 225 | 250 | 300 | ||||

| PEW-2416 | 600*400 | 275 | 30-37 | 26 | 38 | 45 | 60 | 75 | |||||

| PEW-3020 | 750*500 | 250 | 45-55 | 40 | 60 | 70 | 90 | 112 | 130 | ||||

| PEW-3620 | 900*500 | 250 | 55-75 | 45 | 72 | 85 | 100 | 130 | |||||

| PEW-3624 | 900*600 | 250 | 55-75 | 105 | 130 | 160 | 182 | ||||||

| PEW-4226 | 1050*650 | 260 | 75~90 | 150 | 180 | 205 | 255 | ||||||

| PEW-4230 | 1050*750 | 230 | 90-110 | 180 | 210 | 237 | 294 | ||||||

| PEW-4836 | 1200*800 | 230 | 11-160 | 210 | 250 | 280 | 320 | 350 | |||||

| PEW-4836S | 1200*900 | 230 | 110-160 | 210 | 250 | 280 | 320 | 350 | |||||

| PEW-4840 | 1200*1000 | 200 | 132-160 | 265 | 302 | 370 | 402 | ||||||

| PEW-5432 | 1350*800 | 200 | 132-160 | 250 | 300 | 340 | 420 | 450 | |||||

| PEW-6040 | 1500*1000 | 200 | 185-220 | 310 | 350 | 440 | 480 | 510 | |||||

| PEW-6048 | 1500*1200 | 190 | 185-250 | 415 | 500 | 540 | 580 | 630 | |||||

| Model | Max feeding size (mm) | Rotating speed (mm) | Motor power (kW) | Production Capacity (TPH) Closed-side setting (mm) | |||||||||

| 10 | 15 | 20 | 25 | 30 | 40 | 50 | 60 | ||||||

| PEB-248 | 600*200 | 300 | 22-30 | 10.0 | 14.4 | 18.5 | 22.0 | 29.0 | |||||

| PEB-2410 | 600*250 | 300 | 30-37 | 16.5 | 22.0 | 27.0 | 34.0 | 41.0 | |||||

| PEB-368 | 900*200 | 300 | 37-45 | 14.7 | 21.2 | 27.0 | 32.0 | 43.0 | |||||

| PEB-3612 | 900*300 | 300 | 45-55 | 35.0 | 42.0 | 54.0 | 65.0 | ||||||

| PEB-4210 | 1050*250 | 275 | 45-55 | 39.0 | 46.0 | 60.0 | 72.0 | ||||||

| PEB-4215 | 1050*375 | 275 | 55-75 | 50.0 | 70.0 | 84.0 | 90.0 | ||||||