Oil Immersed Power Transformer

Brief Description

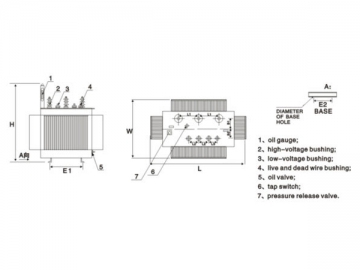

The oil immersed distribution transformer is completely sealed against outside air and moisture to keep transformer oil clean and free from contamination. Flexible corrugated oil tank design (for cooling and heat dissipation) accommodates the change of transformer volume. Insulation material such as high-voltage bushings offers a long service life. There is no need to check up the core yoke before getting the transformer started. No maintenance or repair is required as the distribution transformer will last for years to come. This product is also designed with conservator protection.

Known for outstanding performance and significant energy savings. When equipped with an on-load tap changer, this transformer allows remote voltage control manually or automatically. Extended voltage adjustment range: ±3×3%. Handles large loads with minimum temperature increase in the coil. Rigid construction features a conservator acting as a reservoir for transformer oil. Widely used in hydroelectric power stations as well as power grids requiring constant voltage or involving frequent, dramatic voltage changes.

Applications

Ideal for any power distribution sites as well as European style compact substations and mobile substations

Standards

IEC60076

GB10094

Corrugated tank with fins for heat dissipation

On-load tap changer changes the tap position, which then alters the number of winding turns connected to one circuit thereby adjusting voltage without powering off the circuit.

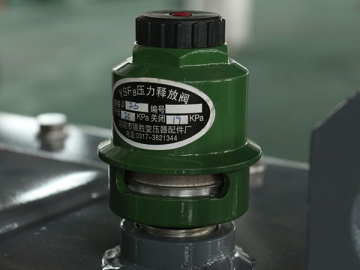

Pressure relief valve ensures safety all while keeping air and moisture out of the transformer oil.

Oil injection port is where oil temperature can be measure.

| S11-30~2500/10 Series Distribution Transformer with Conservator Parameters | |||||||||||||

| Model No. | Rated Voltage | Vector Group | No-Load loss at75 °C | Load loss at 75 °C | No-load Current% | Impedance Voltage % | Weight(kg) | Distance between Yokes | Dimensions (mm) | ||||

| H.V(kV) | % | L.V.(kV) | (W) | (W) | Body | Oil | G.W. | (E1=E2) | LxWxH | ||||

| 6 6.3 10 10.5 11 | ( 1x2.5) 0 (-3 x 2.5)% | 0.4 | 100 | 630/600 | 0.4 | 4 | 195 | 80 | 335 | 400 | 800x620x1000 | ||

| 130 | 910/870 | 0.4 | 280 | 100 | 460 | 400 | 840x650x1100 | ||||||

| 150 | 1090/1040 | 0.4 | 310 | 115 | 500 | 400 | 870x670x1120 | ||||||

| 180 | 1310/1250 | 0.35 | 335 | 125 | 560 | 400 | 900x700x1190 | ||||||

| 200 | 1580/1500 | 0.35 | 420 | 130 | 650 | 400 | 920x720x1210 | ||||||

| 240 | 1890/1800 | 0.30 | 450 | 150 | 740 | 550 | 940x740x1230 | ||||||

| 280 | 2310/2200 | 0.30 | 540 | 170 | 900 | 550 | 960x800x1270 | ||||||

| 298 | 2666/2294 | 0.30 | 630 | 190 | 950 | 550 | 1050x770x1320 | ||||||

| 400 | 3180/3050 | 0.25 | 820 | 210 | 1160 | 550 | 1080x800x1300 | ||||||

| Dyn11 | 480 | 3830/3650 | 0.25 | 900 | 230 | 1400 | 550 | 1080x800x1400 | |||||

| Yyn0 | 570 | 4520/4300 | 0.25 | 1040 | 270 | 1630 | 550 | 1220x830x1460 | |||||

| 680 | 5410/5150 | 0.25 | 1230 | 280 | 1730 | 660 | 1350x830x1500 | ||||||

| 810 | 6200 | 0.23 | 4.5 | 1420 | 350 | 2050 | 660 | 1370x940x1550 | |||||

| 980 | 7500 | 0.23 | 1600 | 400 | 2570 | 820 | 1650x980x1580 | ||||||

| 1150 | 10300 | 0.20 | 1820 | 480 | 2950 | 820 | 1780x1160x1700 | ||||||

| 1360 | 12000 | 0.20 | 2480 | 560 | 3700 | 820 | 1800x1180x1730 | ||||||

| 1640 | 14500 | 0.20 | 3100 | 640 | 4550 | 820 | 1930x1260x1860 | ||||||

| 2020 | 18270 | 0.18 | 3450 | 800 | 5350 | 1070 | 1980x1300x2050 | ||||||

| 2380 | 21210 | 0.18 | 4050 | 900 | 6080 | 1070 | 2000x1300x2180 | ||||||

| Note: Above data are for reference only. | |||||||||||||