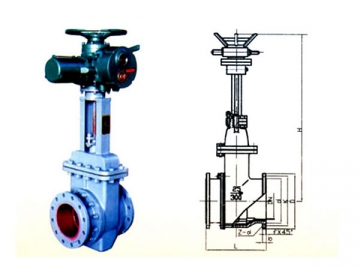

Slagging Gate Valve

Slagging gate valve provided in KIST is mainly applied in the high-temperature water, steam, and oil pipeline of power plants. It is manufactured in compliance with 2 different standards, respectively ANSI B16.34/JIS E101 and JB3595. The working temperature and pressure of the 2 types is consistent, so they can be used interchangeably in certain cases.

The control valve shows good sealing performance even under high temperature and high pressure. Middle part of the valve adopts self-tightening structure. The seal ring of the valve is made from low-carbon steel and flexible graphite 316. On the sealing surface, we have welded a layer of cobalt-based hard alloy, the pure metal layer of which is thicker than 3mm. KIST slagging gate valve is distinguished for high wear resistance, high-temperature resistance, corrosion resistance, and long service life. The welding bevel can be designed according to clients' request.

Main features

1. The flow control valve adopts self-tightening structure, without the need of bonnet

2. Both single-seated resilient wedge valves and double-seated wedge valves are available

3. Cobalt-based hard alloy which has been given surfacing treatment is used for the valve seat

4. Creep deformation technique is employed for resistance to high temperature

5. Nitriding precipitation hardening stainless steel for the valve stem

6. Driving system is available in various styles: manual, gear (bevel gear and spur gear), and electrical