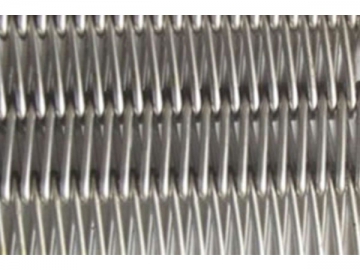

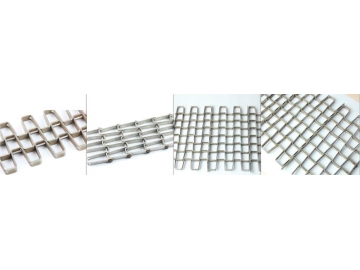

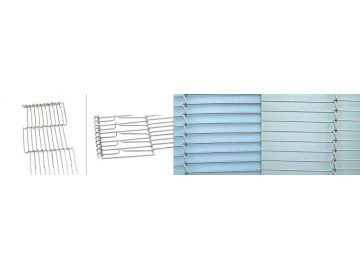

Conveyor Belt Wire Mesh

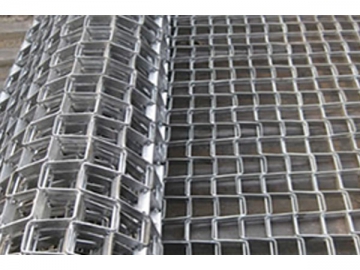

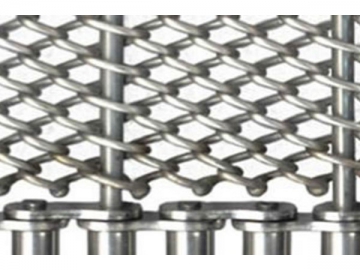

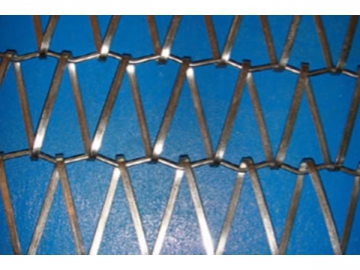

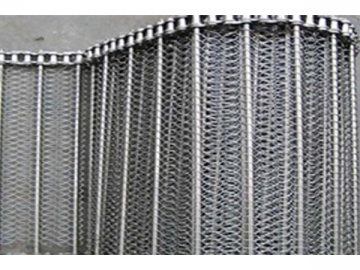

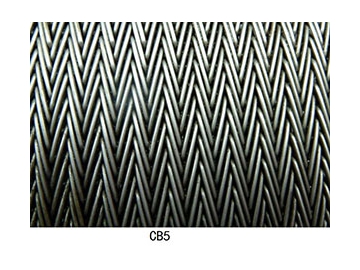

Conveyor belt mesh, also called spiral weave mesh, is a type of decorative metal fabric. It can be subdivided into stainless steel mesh bands, conveyor bands, metal conveyor bands, stainless steel conveyor bands, stainless steel driving bands and metal transmission mesh bands.

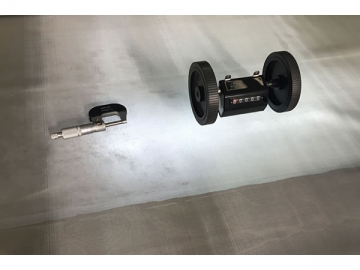

Main Technical Parameters

1. Width: 150-5500mm

2. Speed: 0.15-0.5m/min

3. Service Temperature: -40℃-1300℃

4. Edge Mode: Flanged Edge, Upset Head, Welding, etc

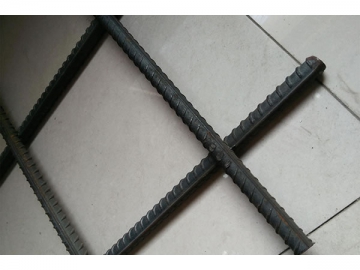

5. Optional Raw Material: low Carbon Steel Wire, Carbon Steel Wire, Galvanized Wire, Stainless Steel Wire, High Temperature Alloy Wire, etc

Features:

1. High open structure - high proportion of open area up to 86% makes the belt efficient in cooling, drying, heating applications.

2. Positive drive without slipping - Rod network belts are normally driven by sprockets positively without need for complicated tracking mechanisms.

3. Stable conveying - With smallest diameter end rolls and drive rolls, the rod network belts provide the stable conveying of delicate products

4. A wide range of sizes - Various sizes with different openness to suit different applications providing superb strength and min contact surface between the products and the belts. Generally, the more the joints cross the width, the stronger the belt.

5. Lower belt mass - low belt mass than balanced weave belts for lower power consumption, faster processing and more product throughput.

6. Cost saving - The high open structure without hidden crevices makes the belt easy to clean and maintain which result in considerable cost savings

Application:

1. The metal conveyor belt is widely used in glass industry as the mesh band of annealing furnaces, decoration firing furnaces, etc.

2. In food processing industry, it can be employed as the pre-processing mesh band and chain mesh for dehydrated vegetables and frozen food single frozen machine.

3. The product can also be applied as the baffle type mesh band, conveying band of painting and drying line, mesh band of nickel foam reduction production line and carburized high temperature furnace mesh band involving powder metallurgy, metal heat treatment, quenching, sintering, braze welding, roasting, bright heat treatment, bluing, bearing, etc.

4. The metal conveyor band is extensively used for mechanical equipment such as cleaning machines, elevators, dryers, curing ovens, etc.

5. As the chain mesh and mesh band, it is widely applied for diversified transportation processes.