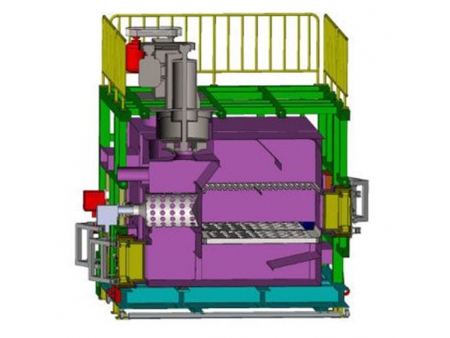

Belt Calciner/Mesh Belt Conveyor Furnace

GWD Series Belt Calciner/Mesh Belt Conveyor Furnace

Continuous high-temperature calcination can be done more efficient with the belt calciner/mesh belt conveyor furnace, widely utilized in industries such as chemicals, catalysts, new energy, and advanced materials. The belt calciner is composed of independent units, each equipped with a circulation fan, heating elements, and fresh air intake and exhaust systems. This design allows for independent control of critical parameters such as air flow, temperature, humidity, and exhaust circulation, ensuring optimized conditions for consistent, reliable performance. The calcination process occurs entirely within the enclosed furnace chamber, ensuring stable operation and high-quality product output. Widely applied in industries such as chemicals, catalysts, and advanced materials, the furnace provides an ideal solution for automated calcination processes.

- Drying and calcination of formed catalysts

- Drying and calcination of automotive catalysts

- Drying and calcination of nitration catalysts

| Model | Mesh belt width (m) | Length of calciner (m) | Working unit | Temperature (℃) | Mesh belt speed (m/min) | Heat for system (10,000 kcal/h) | Drive power (kW) | System power (kW) |

| | 0.6 | 12 | 6 | 100-700 | 0.01-0.20 | 20-40 | 0.75 | 18-20 |

| | 0.6 | 24 | 12 | 100-700 | 0.01-0.40 | 40-80 | 2.2 | 36-38 |

| | 0.8 | 12 | 6 | 100-700 | 0.01-0.20 | 30-60 | 1.1 | 20-22 |

| | 0.8 | 24 | 12 | 100-700 | 0.01-0.40 | 60- 120 | 2.2 | 40-42 |

| | 1.0 | 12 | 6 | 100-700 | 0.01-0.20 | 40-80 | 1.1 | 22-25 |

| | 1.0 | 24 | 12 | 100-700 | 0.01-0.40 | 70- 160 | 2.2 | 40-45 |

| | 1.2 | 12 | 6 | 100-700 | 0.01-0.20 | 50- 100 | 1.5 | 25-30 |

| | 1.2 | 24 | 12 | 100-700 | 0.01-0.40 | 80- 160 | 2.2 | 50-55 |

| | 1.4 | 12 | 6 | 100-700 | 0.01-0.20 | 60- 120 | 1.5 | 35-40 |

| | 1.4 | 24 | 12 | 100-700 | 0.01-0.40 | 100-200 | 3 | 60-70 |

| | 1.6 | 12 | 6 | 100-700 | 0.01-0.20 | 70- 140 | 1.5 | 45-50 |

| | 1.6 | 24 | 12 | 100-700 | 0.01-0.40 | 110-220 | 3 | 70-80 |

- Uniform heating is ensured by a specially designed air distribution system, delivering high-temperature hot air that guarantees consistent product quality

- Independent hot air circulation systems in each unit minimize heat loss and allow for precise temperature management

- Stepwise heating and cooling are applied, protecting the product from sudden temperature changes and preventing thermal shock

- Multiple heat sources, including electric heating, natural gas, and liquefied petroleum gas, offer flexibility for diverse operational requirements

- The continuous operation overcomes the drawbacks of traditional batch systems, enabling easy automation and improved efficiency

- Seamless integration with a dryer allows for smooth transitions between the drying and calcination stages, further enhancing productivity

Need help finding the right product? Please fill the form and we will be in touch with you as soon as possible.