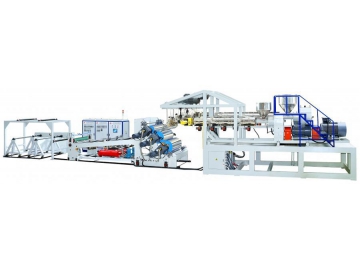

Multi Co-Extrusion Profile Extrusion Line

Profile Extruder, Plastic Profile Extrusion Machinery, Profile Co-Extrusion Line

Basing on market and clients’ demands, Zeqi has developed the multi co-extrusion profile extrusion line basing on our original co-extrusion equipment. This line adopts special screws, and co-extrusion technique to realize better plasticizing and sealing result. We can customize different models of and auxiliary equipment according to different raw materials and applications. The plastic profiles produced by this extrusion line, such as bathroom accessories and automotive rubber seal strips are widely applied in automotive and decoration industries.

-

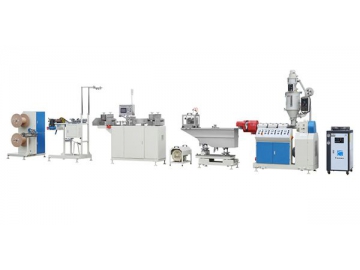

Multi extrusion line

-

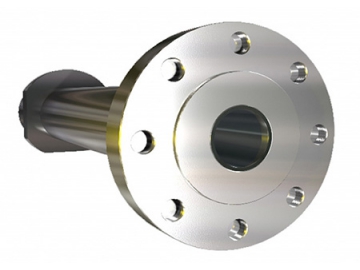

Mold for TPV TPE car door rubber seal strip

-

Automotive seal strip

-

Automotive seal strip

Zeqi introduced the advanced technique from Germany to produce screws. Equipped with different precise molds and different auxiliary lines, the high-performance single screw extruder or multiple co-extrusion devices are able to produce diversified automobile sealing strips of different textures (hard/soft) from different materials such as PVC/SPVC, and TPE (TPV, TPO, TPU). They can basically meet the production needs of auto decorative sealing strips. By replacing the screw barrel, we can apply the extrusion line to process sealing strips for common machineries. This PVC profile extrusion line is used extensively, particularly for making TPV sealing parts, which have gradually witnessed a tendency to be a replacement for rubber sealing parts. Considering the forming effect control and production speed of the extrusion line, Zeqi has been a leading manufacturer in Chinese extrusion industry.

Main performance of TPV dynamically vulcanized thermoplastic EPDM elastomer/ rubber:

TPV is easy to be welded and can be recycled, environmentally friendly and nontoxic.

Main characteristics of TPV dynamically vulcanized thermoplastic EPDM elastomer/ rubber:

1. Excellent ageing resistance and good weather and heat resistance;

2. Excellent resistance to permanent deformation;

3. Excellent tensile strength, high tenacity and rebound resilience;

4. Environmentally friendly and reusable

5. Excellent electrical insulation performance;

6. Wide hardness range;

7. Wide operating temperature range;

8. Diversified colors, including transparent, translucent and light color series; easy coloring, processing and forming;

9. Jointly injected, extracted and formed with multiple materials, i.e. PP, PA, PC, ABS, PS, PBT, PET, etc.

Automobile sealing strips and elements;

Automobile dust cover, mudguard, ventilating pipe, buffer, bellows, air inlet pipe, etc.;

Automobile high-voltage ignition wire, withstanding a high voltage of 30-40KV, and meeting UL94 V0 flame-retardant requirements;

Manual tool, electric tool, weeding machine and other gardening equipment;

Gaskets and parts used on household electrical appliances;

Handles and grips of products such as scissors, toothbrush, fishing rod, sports equipment, kitchenware, etc.;

All kinds of packaging for products such as cosmetic, beverage, food, bath & toilet accessories, medical instruments, etc.;

Soft parts of joints of various wheels, buzzers, pipe fittings, belts, etc.;

Flexible rubber parts of needle plug, bottle plug, suction tube, sleeve, etc.;

Flashlight shell, toy for children, toy tires, golf bag, various grips, etc.

Sheaths and joints of various headphone cable;

Insulation layers and sheaths of mine cables, CNC coaxial cables, general and high-grade wires and cables;

Power socket, plug, sheath, etc.;

Shells of battery and radio telephone, and sheaths of electronic transformer;

Insulation layers and sheaths of power cables for ship, mine, drilling platform, nuclear power station and other facilities

Road and bridge expansion joints;

Road safety facilities, buffer and anti-collision parts;

Container rubber seal strip

Sealing strips of power parts

Building expansion joints and sealing strips

Sealing elements of water supply and drainage pipes, control valves of water irrigation systems, etc.

-

-

-

-

Bath seal strips

| Accessories | Quantity | Remarks | ||

| 1 | 55 main extruder | screw, barrel | 1 | specification: Ф 5 5mm; material: 38CrMoAlA; treatment: quenching and tempering, nitriding, electroplating hard chrome |

| speed reducer | 1 | hardened surface | ||

| air cooling device | 3 | cooling fan: 180W /area | ||

| electronic control cabinet | 1 | constant temperature for area 8, air cooling for area 3 | ||

| motor | 1 | 15 kW-4; variable frequency speed control | ||

| frame | 1 | steel structure | ||

| 2 | 35 assistant extruder | screw, barrel | 1 | diameter: Φ35; material: 38CrMoAlA; treatment: tempering, nitriding, electroplating hard chrome |

| motor | 1 | 4 kW-4; variable frequency speed control | ||

| temperature control | constant temperature for area 5 | |||

| 3 | Vacuum sizing device | 1 | the bracket can move up and down automatically | |

| 4 | Crawler traction machine | 1 | 0.75kW motor; variable frequency control | |

| 5 | Cutting machine | 1 | auto cutting with certain length or manual cutting |

-

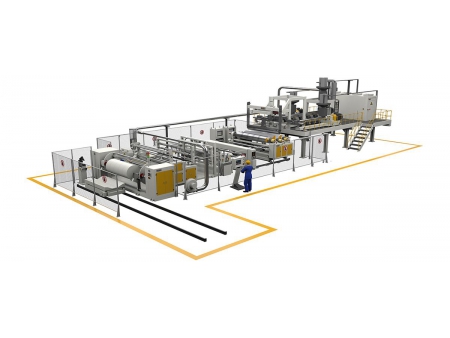

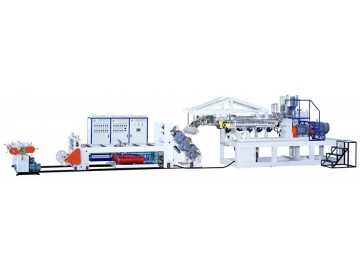

Tripe extrusion line

-

Bath seal strips

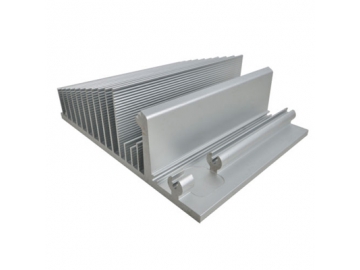

Hard PVC soft PVC

Technical Parameters| Accessories | Quantity | Remarks | ||

| 1 | 55 main extruder | screw, barrel | 1 | specification: Ф 5 5mm; material: 38CrMoAlA; treatment: quenching and tempering, nitriding, electroplating hard chrome |

| speed reducer | 1 | hardened surface | ||

| air cooling device | 3 | cooling fan: 180W /area | ||

| electronic control cabinet | 1 | constant temperature for area 8, air cooling for area 3 | ||

| motor | 1 | 15 kW-4; variable frequency speed control | ||

| frame | 1 | steel structure | ||

| 2 | 35 assistant extruder | screw, barrel | 2 | diameter: Φ35; material: 38CrMoAlA; treatment: tempering, nitriding, electroplating hard chrome |

| motor | 2 | 4 kW-4; variable frequency speed control | ||

| temperature control | constant temperature for area 5 | |||

| 3 | Vacuum sizing device | 1 | the bracket can move up and down automatically | |

| 4 | Crawler traction machine | 1 | 0.75kW motor; variable frequency control | |

| 5 | Cutting machine | 1 | auto cutting with certain length or manual cutting | |

| 6 | Magnetic strip delivery and heating device | 1 |