DRW-Multi Robotic Waterjet Cutting Machine

The multi robotic waterjet cutting machine features an open design and is equipped with two workstations. It is ideal for cutting large, highly precise car interior components, such as the car carpet and ceiling.

Due to the multiple workstation design, it will simultaneously load and cut to minimize downtime. Different workstations can process the same or different types of workpieces simultaneously, and the robotic waterjet cutting machine can be upgraded to a single robot with 4 workstations, or two robots with 3 workstations according to different application needs.

The robotic waterjet cutting machine is installed upright on the base. The workstations are installed on both sides, allowing the robot to alternate workpiece cutting between the two workstations. This allows the workstation on one side to be cutting while the workstation on the other side is loading and unloading, thus ensuring continuous production. This equipment can also use two robots simultaneously to work together and improve productivity.

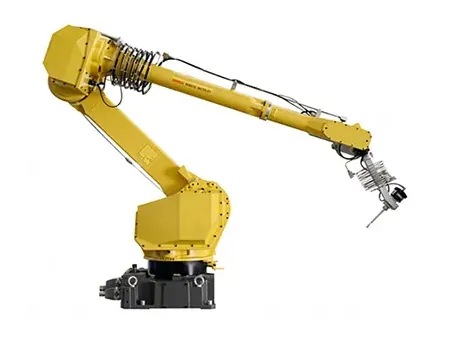

The multi robotic waterjet cutting machine uses different robot systems, including ABB, FANUC, and YASKAW for a high precision and stable operation.

| Software | ABB/FANUC/YASKAWA(optional) |

| Arm reach | 3180mm |

| Cutting area | 2600×1700×200mm |

| Speed | 300mm/s |

| Cutting table | Single work station/two work station/three work station/four work station |

| Power | 60kW(single work station), 75kW(two work station) |

| CNC control system | ESA |

We are pleased to customize the waterjet robot to meet your special requirements.