Fluidized Tunnel Freezer

Request a Quote

Cold Chain System Solution

Freezing System, Tunnel Freezer Manufacturer

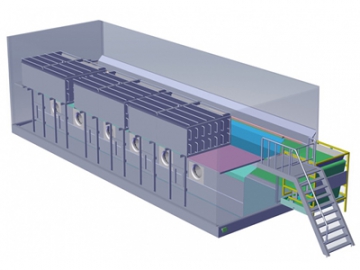

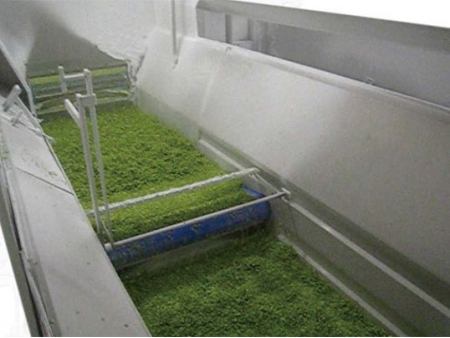

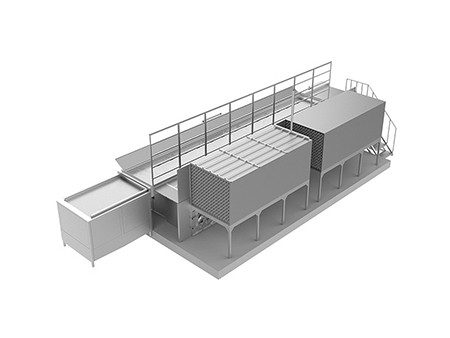

The fluidized tunnel freezer is used to freeze small pieces of food, which can range from sliced or diced vegetables, fruits, and berries to meat, poultry, seafood such as small fish or shrimp, and small dairy products or cooked products. The freezer is equipped with a highly efficient and sanitary evaporator, using the latest liquid supply method, with a heat exchange 20% higher than traditional methods. We have two types: semi-fluidized and full-fluidized, which meets different product freezing application.

Parameters| Items | Parameters | Parameters |

| Model | FBF-V-ADF | FBF-NA50RS01 |

| Freezing capacity | 5T (Green peas) | 5T(Green peas) |

| Freezer size length×Width×Height (mm) | 18310×4610×4175 | 9180×5060×4900 |

| Mesh belt width (mm) | 1370 | 1370 |

| Effective width (mm) | 1170 | 1250 |

| Freezing temperature (℃) | -35±2 | -35±2 |

| Feed temperature (℃) | 10 | 15℃ |

| Discharge temperature (℃) | - 18 | -18℃ |

| Energy consumption (kw) T0=-42℃,TK= 35℃ | 650 | 650 |

| Installed capacity (kw) | 132 | 115 |

| Refrigerants | R717 | R717 |

| Air defroster device Number of evaporators (group) | 2 | 2 |

| Defrosting methods | Air/water defrosting | Air/water defrosting |

| Cycle time of frozen products from infeed to outfeed | 6-30min | 6-30min |

- The fluidized tunnel freezer uses a food-grade stainless steel mesh belt, which is easy to clean and corrosion resistant.

- It is equipped with a stainless steel centrifugal fan for an excellent cooling performance.

- It is equipped with an impingement device for conveyor belt to ensure a single freezing efficiency of frozen products.

- The fluidized tunnel freezer uses an imported cold storage insulated panel production line for panel production, which is both energy efficient and high quality.

- The freezing equipment is equipped with an intelligent central control system, automatic detection device and warning lights, which is easy for users to operate and maintain.

- We can design and manufacture the freezer based on different frozen food conditions and customer requirements.

- The production capacity ranges between 1000kg/h and 6000kg/h.

- The ADF air defrost system is suitable for continuous defrosting, thus allowing the freezer to work continuously.

- The remotely controlled system is optional, which solves any problems for customers during production.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos