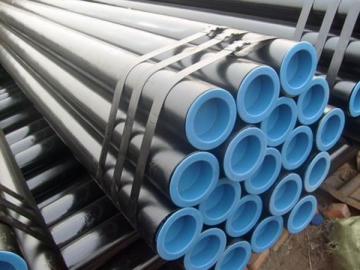

Boiler Tube

The seamless steel tube is mainly used in the low and medium pressure industrial boilers. Pressure is not over 3.9MPa.

Specifications

Standards: GB/T3087-2008, ASTM A179, ASTM A192,BS3059

Materials: 10#, 20#

Sizes:

O.D.: 10-426mm

Wall thickness: 1.5-26mm

Length: Any length, Customized

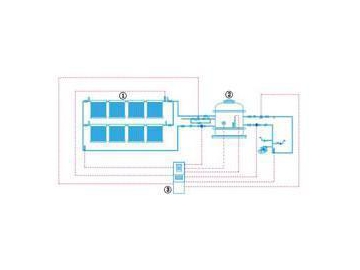

Applications

The seamless pipe is excellent for making all kinds of steam pipes and boiling water tubes for low and medium pressure boilers as well as overheat steam tube, flue tube and arch tube for locomotive boiler.

| Boiler tube standard | Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

| GB3087 | 10 | 335-475 | ≥195 | ≥24 |

| 20 | 410-550 | ≥245 | ≥20 |

| Steel tube Standard | Grade | Compositions | |||||||||

| C | Si | Mn | P | S | Cr | Mo | Cu | Ni | V | ||

| GB3087 | 10 | 0.07-0.14 | 0.17-0.37 | 0.35-0.65 | ≤0.035 | ≤0.035 | ≤0.15 | / | ≤0.25 | ≤0.25 | / |

| 20 | 0.17-0.24 | 0.17-0.37 | 0.35-0.65 | ≤0.035 | ≤0.035 | ≤0.25 | / | ≤0.25 | ≤0.25 | / | |

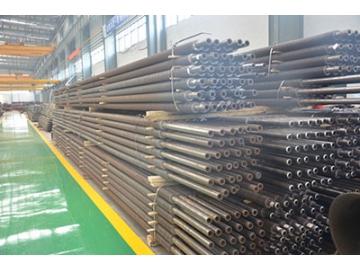

Production Capacity: 50,000 tons per year

Production Cycle, Packaging, Delivery

Production cycle of the boiler tubing is about two weeks. So in-time delivery can be guaranteed. Without special requirements, we provide bundling package or conduct export packing as required.

Raw Materials

The seamless steel tube is made of the superior steels from Tianjin Iron and Steel Co., Ltd. They result in reliable quality.

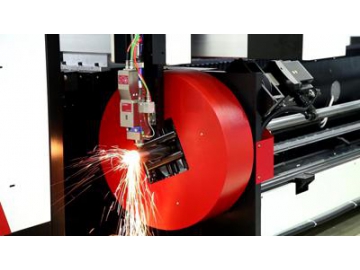

Production Process

Pipe billets inspection—Cutting of qualified billets—Heating—Hot piercing—Tube rolling—Stretch reducing—Cooling on cold bed—Straightening—Cutting—Eddy current testing—Manual surface testing—Packaging—Weighing and Putting in storage