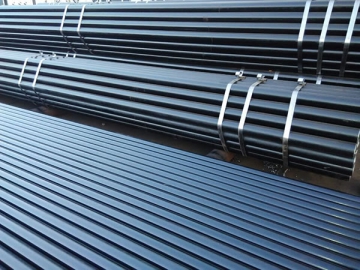

Structural Steel Tube

Specifications

Standards: GB/T8162-2008, ASTM A500-98,ASTM A501-98, ASTN A519-98, JIS G3441-1994, GOST 8731-74, GOST8732-78

Main Materials: 10#, 20#, 45#, 40Mn2, 45Mn2, 27SiMn, 20Cr, 40Cr, 20CrMo, 35CrMo, 42CrMo, 30CrMnSi

Sizes:

O.D.: 1/2"-24",

Wall thickness: SCH40/80/120/160, etc.

Length: max. 12m or customized

Applications

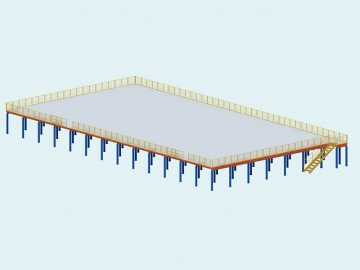

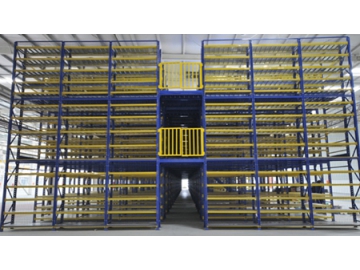

The structural steel tube is a seamless steel tube for structural tubing. It is used on machinery or in buildings as steel frame or steel constructions. In addition, the steel pipe is used in general projects for supporting applications.

| Standard | Material | Chemical Compositions | |||||||

| C | Si | Mn | P 、 S | Cu | Ni | Mo | Cr | ||

| GB/T8162 | 10 | 0.07~0.14 | 0.17~0.37 | 0.35~0.65 | ≤0.035 | ≤0.25 | ≤0.25 | / | ≤0.15 |

| 20 | 0.17~0.24 | 0.17~0.37 | 0.35~0.65 | ≤0.035 | ≤0.25 | ≤0.25 | / | ≤0.25 | |

| 35 | 0.32~0.40 | 0.17~0.37 | 0.50~0.80 | ≤0.035 | ≤0.25 | ≤0.25 | / | ≤0.25 | |

| 45 | 0.42~0.50 | 0.17~0.37 | 0.50~0.80 | ≤0.035 | ≤0.25 | ≤0.25 | / | ≤0.25 | |

| 16Mn | 0.12~0.20 | 0.20~0.55 | 1.20~1.60 | ≤0.035 | ≤0.25 | ≤0.25 | / | ≤0.25 | |

| 12CrMo | 0.08~0.15 | 0.17~0.37 | 0.40~0.70 | ≤0.035 | ≤0.25 | ≤0.30 | 0.40~0.55 | 0.40~0.70 | |

| 15CrMo | 0.12~0.18 | 0.17~0.37 | 0.40~0.70 | ≤0.035 | ≤0.25 | ≤0.30 | 0.40~0.55 | 0.80~1.10 | |

| 12Cr1MoV | 0.08~0.15 | 0.17~0.37 | 0.40~0.70 | ≤0.035 | ≤0.25 | ≤0.30 | 0.25~0.35 | 0.90~1.20 [1] | |

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

| 10 | ≥335 | ≥205 | ≥24 |

| 20 | ≥390 | ≥245 | ≥20 |

| 45 | ≥590 | ≥335 | ≥14 |

| Q345 | ≥490 | ≥325 | ≥21 |

| 15CrMo | ≥440 | ≥295 | ≥22 |

| 12Cr1MoV | ≥490 | ≥245 | ≥22 |

Production Capacity: 130,000 tons per year

Production Cycle, Packaging, Delivery

The production cycle of the structural steel tube is about two weeks which ensure in-time delivery. If there are no special requirements, we will bundle them or conduct export packing as required.

Raw Materials

Our seamless structural tubing is made of the superior steels from Tianjin Iron and Steel Co., Ltd., ensuring reliable quality.

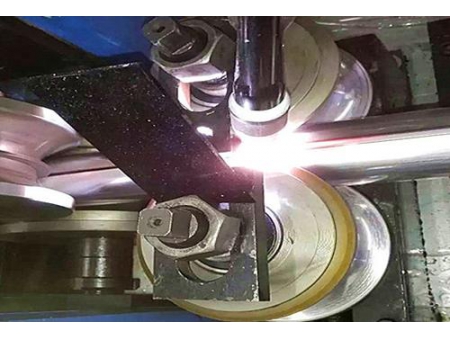

Production Process

Pipe billets inspection---Cutting of qualified billets---Heating---Hot piercing---Tube rolling---Stretch reducing---Cooling on cold bed---Tube cutting---Eddy current testing---Manual surface testing---Packaging---Weighing and Putting in storage