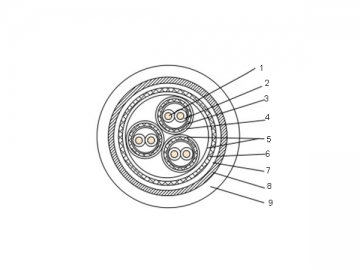

Petroleum and Chemical Plant Control Cable

Standards It is manufactured according to Q/320411AVX006 (refer to GB/T 9330, IEC60227) standards.

The flame-retardant cables comply with GB/T 18380 (IEC60332-3) standards.

The fire resistant cables comply with GB /T 19216.21 (IEC60331-21) standards.

The low-smoke and low-halogen cables comply with GB /T 17651 (IEC61034), GB/T 17650.1 (IEC60754-1) standards.

The low-smoke and halogen-free cables comply with GB /T 17651 (IEC61034), GB/T 17650.2 (IEC60754-2) standards.

Application These petroleum and chemical plant control cables are used for signal transmission, control and measurement systems in the electronic components and power distribution equipment in metallurgy, power and petroleum facilities. They have a rated voltage of up to 450/750V.

The fire resistant control cable is used for controlling, inspection and protective circuitry of which rated voltage is up to including 450/750V, where has the high requirement of flame-proof.

Specifications Note: the specifications are for the XLPE control cables and fire-resisting control cables with PVC jacket.

| Size | | |||||

| Max. Diameter | Calculated mass | Max. Diameter | Calculated mass | Max. Diameter | Calculated mass | |

| mm2 | mm | kg/km | mm | kg/km | mm | kg/km |

| 2×0.5 | 14.5 | 330 | 13.0 | 205 | 13.0 | 190 |

| 3×0.5 | 15.0 | 355 | 13.5 | 215 | 13.5 | 210 |

| 4×0.5 | 16.0 | 405 | 15.0 | 260 | 14.5 | 240 |

| 5×0.5 | 18.0 | 535 | 16.0 | 325 | 16.0 | 300 |

| 6×0.5 | 19.0 | 590 | 17.0 | 355 | 16.5 | 330 |

| 7×0.5 | 19.0 | 600 | 17.0 | 365 | 16.5 | 340 |

| 8×0.5 | 20.0 | 665 | 18.5 | 425 | 18.0 | 380 |

| 10×0.5 | 22.5 | 785 | 20.5 | 515 | 20.0 | 450 |

| 12×0.5 | 23.0 | 830 | 21.0 | 550 | 20.5 | 495 |

| 14×0.5 | 24.5 | 1030 | 22.0 | 595 | 21.5 | 540 |

| 16×0.5 | 25.5 | 1090 | 23.0 | 645 | 22.5 | 580 |

| 18×0.5 | 26.5 | 1165 | 24.0 | 705 | 23.5 | 625 |

| 19×0.5 | 26.5 | 1175 | 24.0 | 715 | 23.5 | 640 |

| 24×0.5 | 29.5 | 1390 | 27.0 | 870 | 26.5 | 780 |

| 27×0.5 | 30.5 | 1470 | 27.5 | 920 | 27.5 | 840 |

| 30×0.5 | 31.5 | 1555 | 28.5 | 980 | 28.0 | 895 |

| 37×0.5 | 33.0 | 1730 | 30.5 | 1130 | 30.0 | 1025 |

| 44×0.5 | 37.5 | 2240 | 34.0 | 1315 | 33.0 | 1195 |

| 48×0.5 | 38.5 | 2360 | 35.0 | 1415 | 34.0 | 1275 |

| 52×0.5 | 39.0 | 2450 | 35.5 | 1490 | 35.0 | 1380 |

| 61×0.5 | 41.0 | 2705 | 37.5 | 1675 | 37.0 | 1555 |

| 2×0.75 | 15.0 | 355 | 13.5 | 220 | 13.5 | 200 |

| 3×0.75 | 15.5 | 375 | 14.0 | 245 | 14.0 | 235 |

| 4×0.75 | 17.5 | 525 | 15.5 | 315 | 15.0 | 265 |

| 5×0.75 | 18.5 | 580 | 16.5 | 355 | 16.5 | 330 |

| 6×0.75 | 20.0 | 660 | 18.0 | 420 | 17.5 | 375 |

| 7×0.75 | 20.0 | 670 | 18.0 | 430 | 17.5 | 390 |

| 8×0.75 | 21.0 | 735 | 19.0 | 470 | 18.5 | 425 |

| 10×0.75 | 24.5 | 990 | 21.5 | 570 | 21.0 | 510 |

For more details, please download the PDF!