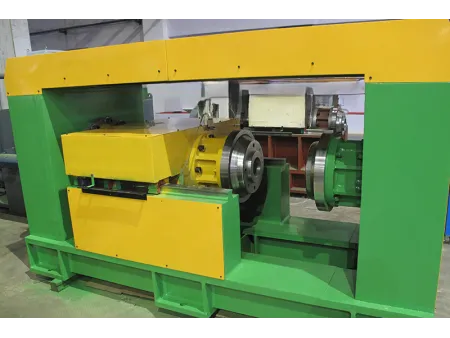

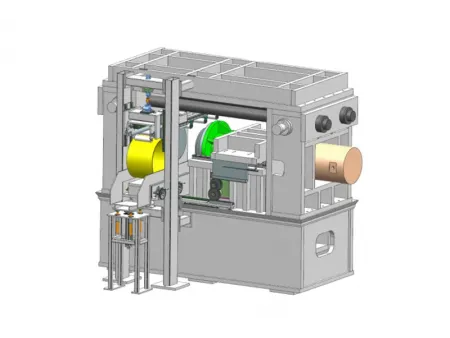

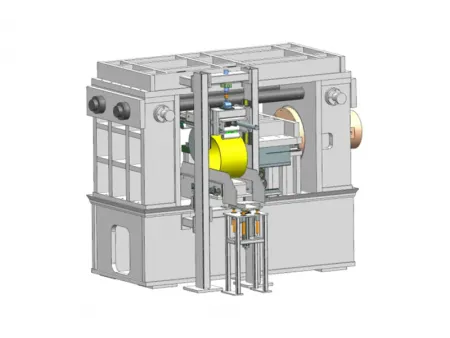

Horizontal Flaring Machine (Flare Press)

Request a Quote

Wheel rim machine used in steel wheel production line prior to the roll forming process

The horizontal flaring machine is used in the steel wheel production line to perform the initial flaring of the coiled and welded hoop to start the rim profiling operation. Also known as a flare press, it flares both sides of the welded and trimmed rim that helps shape the rim accurately, ensuring a smooth transition in the roll forming process.

Process Flow Process Flow

- After re-rounding

- Flaring

Specifications

| Model | |||

| Power supply | AC 380V/3phase/50HZ | AC 380V/3phase/50HZ | AC 380V/3phase/50HZ |

| Rated power | 46kW | 55kW | 62kW |

| Wheel rim thickness | ≤5mm | ≤8mm | ≤10mm |

| Wheel rim width | 200-400mm | 220-500mm | 400-800mm |

| Wheel rim diameter | 350-480mm | 420-580mm | 475-1000mm |

| Max. capacity of hydraulic cylinder | 2200KN | 2500KN | 2800KN |

| Flaring cylinder stroke | 320mm | 400mm | 480mm |

| Max. opening of workbench | 700mm | 800mm | 1100mm |

| Machine weight (with feeder) | 25T | 28T | 38T |

Features

- The flaring machine base is constructed from thick steel plates, ensuring stability throughout the flaring process.

- The flare press and the automated loading/unloading system are compactly structured to save space in the production line.

- A large-diameter hydraulic cylinder provides strong, reliable flaring power.

- Two support rods on the upper frame enhance the machine’s strength and longevity, ensuring consistent precision.

- The left and right sides are reinforced with upper and lower plates, forming a closed structure that significantly increases rigidity and precision.