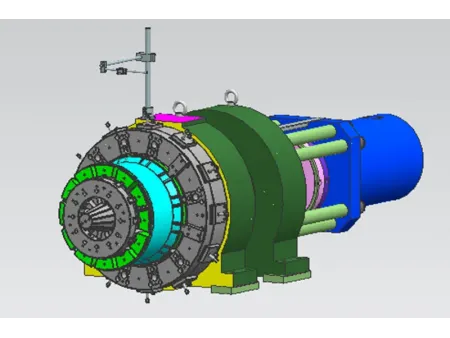

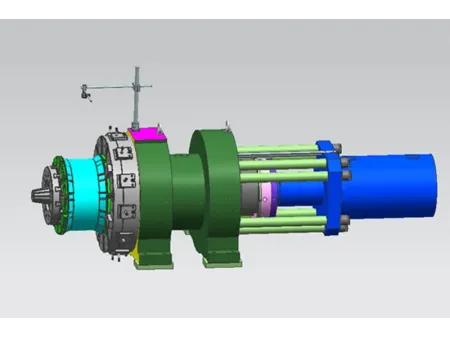

Cone Expansion Rim Flaring Machine

Request a Quote

The cone expansion flaring machine is a dedicated piece of equipment designed for wheel rim flaring operations. It expands both sides of a welded and trimmed wheel rim into a bell-mouth profile, creating the required geometry for subsequent rim rolling and forming operations.

Specifications

- Max. flaring force: 315T

- Cone angle: 10°

- Flaring die segments: 12

- Flaring hydraulic cylinder stroke: 310mm

- Installed power: approx. 75kW

- Machine weight: approx. 8t (excluding base)

Processing StageProcessing Stage

- After re-rounding

- Flaring

Features

- Machine frame: Fabricated from thick steel plates using welded construction. The frame undergoes post-weld stress-relief annealing, ensuring excellent rigidity, dimensional stability, and long-term accuracy.

- Guide bushings: Made of wear-resistant tin bronze. After assembly, the bushings are precision fine-bored to guarantee guiding accuracy and smooth motion.

- Flaring tooling system: The expansion die assembly is fixed to the main machine frame. When changing rim specifications, only the tooling modules need to be replaced, enabling fast model changeover.

- Center height adjustment: Spacer plates are designed at the lower part of the machine frame. During commissioning, the center height can be precisely adjusted by machining the spacer plates.

- Crack detection system: Equipped with Keyence sensors combined with a vision inspection system, providing high-precision detection of flaring cracks and defects to ensure product quality.