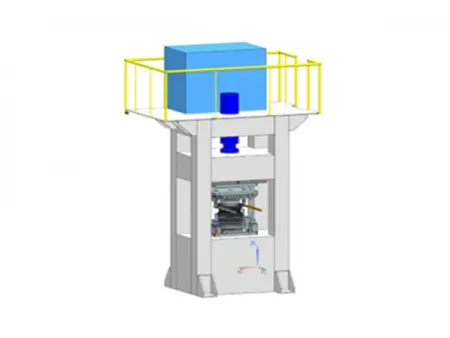

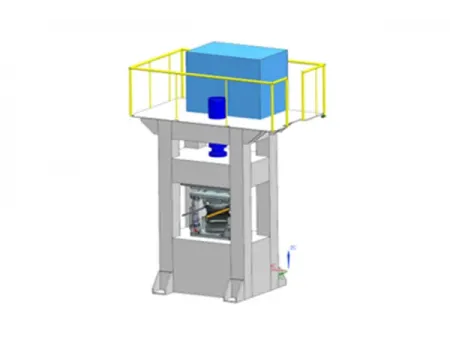

Steel Wheel Assembly Press (Press Fitting Machine)

Request a Quote

4-column hydraulic press with tool sets used to position and press a wheel disc into a wheel rim to form a steel wheel

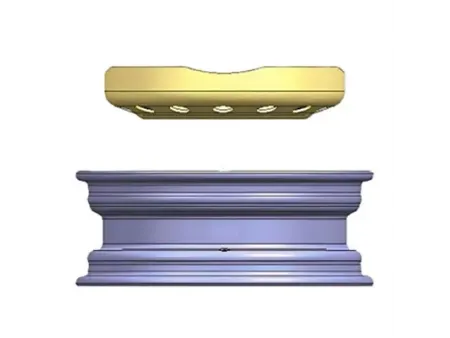

The steel wheel assembly press is a 4-column hydraulic press designed to assemble wheel rims and wheel discs into a single, complete steel wheel. This assembly press utilizes specialized tool sets to accurately position the wheel disc within the rim and apply precise pressure to form a unified wheel structure. Comprised of a four-column press frame and assembly molds, the press fitting machine ensures reliable alignment and secure fitting, essential for producing durable, high-performance wheels.

Process Flow Process Flow

- Press fitting

Specifications

| Model | ||

| Power supply | AC 380V/3phase/50HZ | AC 380V/3phase/50HZ |

| Rated power | 26kW | 32kW |

| Press capacity | 80T | 100T |

| Return pressure | 10T | 12T |

| Work stroke | 600mm | 800mm |

| Workbench size | 700×1200mm | 1000×1500mm |

Features

- All welded components are manufactured through an integrated design process that includes welding and stress relief to ensure durability and precision.

- The control panel on the electrical cabinet features various selector switches, operation buttons, and a customizable touchscreen for centralized control and monitoring of the press.

- Equipped with a main power switch, contactors, thermal relays, and other electrical components, the control box provides complete motor control and protection.

- The primary structure is welded from thick steel plates, enhancing stability and ensuring reliable performance.