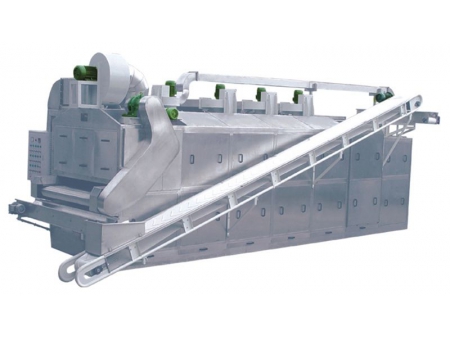

Belt Dryer

Descriptions

This series of belt dryer works by spreading raw material on the conveyor belt and then passing it through the suitable auxiliary mechanism such as a distributor, vibrating belt, pulverizer or granulator. The conveyor then passes through a heating unit. The drying device has channels that each have exhaust systems to remove the evaporated moisture from the material.

Applications

The belt dryer is a continuous drying unit that is widely used for chemical, food, pharmaceutical and construction applications. These drying machines are particularly suitable for drying sheets, strips or granules of raw materials. It can handle filter cakes and pastes but only after they have been through one drying process or a granulator.

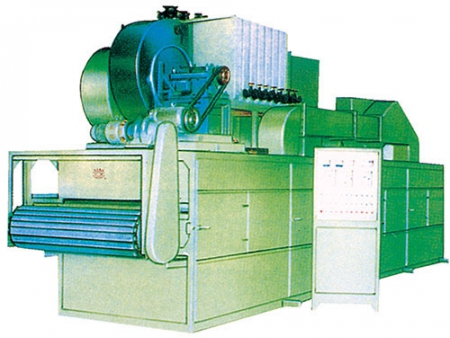

Features

1. Adjustable air amount, time and temperature for the best drying effects.

2. Flexible equipment configuration for heating, washing and cooling processes.

3. Great energy savings.

4. Unique air dividing apparatus for more uniform air distribution.

5. Steam, heat conduction oil, electricity or coal (oil) hot air furnace heat sources.

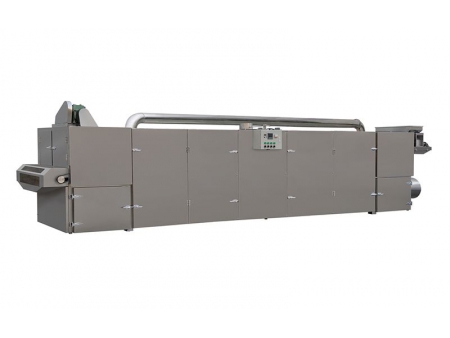

Typical Products

Dehydrated vegetables, granulated feedstuff, monosodium glutamate, chicken abstract, shredded coconut stuffing, organic pigment, synthetic rubber, PP fiber, medicines, medicinal materials, small wood products, plastic products, aging and solidifying of electronics elements, calcium carbonate, white carbon black dyestuff and so on.

Technical Parameters

Model Selection| Model | DW-1.2-8 | |

| Quantity of unit | 4 | |

| Width of belt(m) | 1.2 | |

| Length of dry section(m) | 8 | |

| Thickness of raw material spreading(mm) | 10-80 | |

| Operation temperature(℃) | 50~120 | |

| Steam pressure(Mpa) | 0.2~0.5 | |

| Steam consumption(kg/h) | 120-130 | |

| Area of heat exchange(m2) | 272 | |

| Dry time(h) | 0.2-1.2 | |

| Dry capacity(kg water/h) | 60-160 | |

| Quantity of fan | 5 | |

| Total equipped power inside(kw) | 9.9 | |

| Total equipped power(kw) | 11.4 | |

| Overall dimensions | L(m) | 9.77 |

| W(m) | 1.5 | |

| H(m) | 2.83 | |

| Weight(kg) | 4800 | |

| Model | DW-1.2-10 | |

| Quantity of unit | 5 | |

| Width of belt(m) | 1.2 | |

| Length of dry section(m) | 10 | |

| Thickness of raw material spreading(mm) | 10-80 | |

| Operation temperature(℃) | 50~120 | |

| Steam pressure(Mpa) | 0.2~0.5 | |

| Steam consumption(kg/h) | 150-375 | |

| Area of heat exchange(m2) | 340 | |

| Dry time(h) | 0.25-1.5 | |

| Dry capacity(kg water/h) | 80-220 | |

| Quantity of fan | 6 | |

| Total equipped power inside(kw) | 12.1 | |

| Total equipped power(kw) | 13.6 | |

| Overall dimensions | L(m) | 11.77 |

| W(m) | 1.5 | |

| H(m) | 2.83 | |

| Weight(kg) | 5780 | |

| Model | DW-1.6-8 | |

| Quantity of unit | 4 | |

| Width of belt(m) | 1.6 | |

| Length of dry section(m) | 8 | |

| Thickness of raw material spreading(mm) | 10-80 | |

| Operation temperature(℃) | 50~120 | |

| Steam pressure(Mpa) | 0.2~0.5 | |

| Steam consumption(kg/h) | 150-375 | |

| Area of heat exchange(m2) | 352 | |

| Dry time(h) | 0.2-1.2 | |

| Dry capacity(kg water/h) | 75-220 | |

| Quantity of fan | 5 | |

| Total equipped power inside(kw) | 9.9 | |

| Total equipped power(kw) | 11.4 | |

| Overall dimensions | L(m) | 9.77 |

| W(m) | 2.24 | |

| H(m) | 2.83 | |

| Weight(kg) | 5400 | |

| Model | DW-1.6-10 | |

| Quantity of unit | 5 | |

| Width of belt(m) | 1.6 | |

| Length of dry section(m) | 10 | |

| Thickness of raw material spreading(mm) | 10-80 | |

| Operation temperature(℃) | 50~120 | |

| Steam pressure(Mpa) | 0.2~0.5 | |

| Steam consumption(kg/h) | 170-470 | |

| Area of heat exchange(m2) | 440 | |

| Dry time(h) | 0.25-1.5 | |

| Dry capacity(kg water/h) | 95-250 | |

| Quantity of fan | 6 | |

| Total equipped power inside(kw) | 12.1 | |

| Total equipped power(kw) | 13.6 | |

| Overall dimensions | L(m) | 11.77 |

| W(m) | 2.24 | |

| H(m) | 2.83 | |

| Weight(kg) | 6550 | |

| Model | DW-2-8 | |

| Quantity of unit | 4 | |

| Width of belt(m) | 2 | |

| Length of dry section(m) | 8 | |

| Thickness of raw material spreading(mm) | 10-80 | |

| Operation temperature(℃) | 50~120 | |

| Steam pressure(Mpa) | 0.2~0.5 | |

| Steam consumption(kg/h) | 180-500 | |

| Area of heat exchange(m2) | 448 | |

| Dry time(h) | 0.2-1.2 | |

| Dry capacity(kg water/h) | 100-260 | |

| Quantity of fan | 5 | |

| Total equipped power inside(kw) | 18.2 | |

| Total equipped power(kw) | 19.7 | |

| Overall dimensions | L(m) | 9.77 |

| W(m) | 2.66 | |

| H(m) | 3.5 | |

| Weight(kg) | 6350 | |

| Model | DW-2-10 | |

| Quantity of unit | 5 | |

| Width of belt(m) | 2 | |

| Length of dry section(m) | 10 | |

| Thickness of raw material spreading(mm) | 10-80 | |

| Operation temperature(℃) | 50~120 | |

| Steam pressure(Mpa) | 0.2~0.5 | |

| Steam consumption(kg/h) | 225-600 | |

| Area of heat exchange(m2) | 560 | |

| Dry time(h) | 0.25-1.5 | |

| Dry capacity(kg water/h) | 120-300 | |

| Quantity of fan | 6 | |

| Total equipped power inside(kw) | 22.2 | |

| Total equipped power(kw) | 23.7 | |

| Overall dimensions | L(m) | 11.77 |

| W(m) | 2.66 | |

| H(m) | 3.5 | |

| Weight(kg) | 7800 | |

Note:

1. The vaporized amount of water should be assured in accordance with the dry temperature, thickness of raw material spreading and stay time.

2. The dimensions are just for reference.