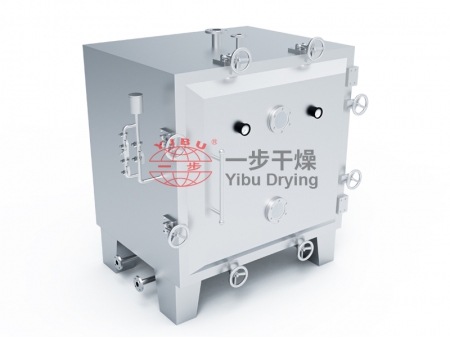

Tray Dryer

Description

The CT-C series hot air circle oven dryer is a basic tray dryer, which is suitable for most materials drying applications. The structure is simple in its design and is easily configured for daily operation. This type of oven dryer is perfect for small capacity operations without continuous drying requirements.

Applications

The drying equipment is suitable for heating and solidification, drying and dehydration of raw materials for pharmaceutical, chemical, food and agricultural applications.

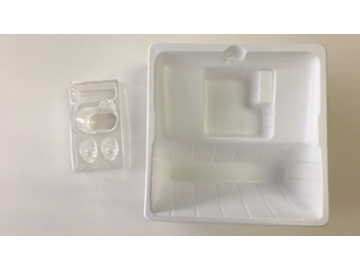

- tray without holes

- tray with holes

- handmade '井' Shape tray

- trolleys with trays

Engineering Projects

Features

1. High thermal efficiency through hot air circulation.

2. Enhanced ventilation and adjustable air divider plate inside the oven for even drying of raw materials.

3. Steam, hot water, electric, heat-conducting oil and hot air from a furnace can all be used as the heat source.

4. Automatic temperature control with low noise and stable operation

5. Convenient installation and maintenance.

6. Suitable for a huge variety of raw materials.

Technical parameters

| Model | Drying area | Capacity (kg/batch) | Fan power (kw) | Steam consumption (kg/h) | Radiation area(m2) | Electrical heater power(kw) | Overall dimension L,W,H(mm) | Door | Trolley | Tray | weight(kg) |

| CT-C-O | 7.1 | 60 | 0.45 | 10 | 10 | 6 | 1200×1000×1750 | 1 | 1 | 24 | 820 |

| Model | Drying area | Capacity (kg/batch) | Fan power (kw) | Steam consumption (kg/h) | Radiation area(m2) | Electrical heater power(kw) | Overall dimension L,W,H(mm) | Door | Trolley | Tray | weight(kg) |

| CT-C-1 | 14.1 | 120 | 0.45 | 18 | 20 | 15 | 2300×1200×2000 | 2 | 2 | 48 | 1580 |

| Model | Drying area | Capacity (kg/batch) | Fan power (kw) | Steam consumption (kg/h) | Radiation area(m2) | Electrical heater power(kw) | Overall dimension L,W,H(mm) | Door | Trolley | Tray | weight(kg) |

| CT-C-1A | 14.1 | 120 | 0.45 | 18 | 20 | 15 | 1200×2200×2000 | 1 | 2 | 48 | 1580 |

| Model | Drying area | Capacity (kg/batch) | Fan power (kw) | Steam consumption (kg/h) | Radiation area(m2) | Electrical heater power(kw) | Overall dimension L,W,H(mm) | Door | Trolley | Tray | weight(kg) |

| CT-C-2 | 28.3 | 240 | 0.45×2 | 36 | 40 | 30 | 2300×2200×2000 | 2 | 4 | 96 | 1800 |

| Model | Drying area | Capacity (kg/batch) | Fan power (kw) | Steam consumption (kg/h) | Radiation area(m2) | Electrical heater power(kw) | Overall dimension L,W,H(mm) | Door | Trolley | Tray | weight(kg) |

| CT-C-2A | 28.3 | 240 | 0.45×2 | 36 | 40 | 30 | 4460×1200×2290 | 4 | 4 | 96 | 1880 |

| Model | Drying area | Capacity (kg/batch) | Fan power (kw) | Steam consumption (kg/h) | Radiation area(m2) | Electrical heater power(kw) | Overall dimension L,W,H(mm) | Door | Trolley | Tray | weight(kg) |

| CT-C-3 | 42.4 | 360 | 0.45×3 | 54 | 80 | 45 | 3430×2200×2000 | 3 | 6 | 144 | 2100 |

| Model | Drying area | Capacity (kg/batch) | Fan power (kw) | Steam consumption (kg/h) | Radiation area(m2) | Electrical heater power(kw) | Overall dimension L,W,H(mm) | Door | Trolley | Tray | weight(kg) |

| CT-C-3A | 42.4 | 360 | 0.45×3 | 54 | 80 | 45 | 2300×3200×2000 | 2 | 6 | 144 | 2210 |

| Model | Drying area | Capacity (kg/batch) | Fan power (kw) | Steam consumption (kg/h) | Radiation area(m2) | Electrical heater power(kw) | Overall dimension L,W,H(mm) | Door | Trolley | Tray | weight(kg) |

| CT-C-4 | 56.5 | 480 | 0.45×4 | 72 | 100 | 60 | 4460×2200×2290 | 4 | 8 | 192 | 2800 |

Notes

1. The information above is for standard drying ovens with a steam radiator or electrical heater and with a drying temperature of 50~140℃.

2. The power listed above is for the axial flow fan (Default hot-air circulating fan).Centrifugal fan is optional.

3. The outer cover of the oven is made of carbon steel or stainless steel. The inner shell is constructed from aluminum alloy or stainless steel. The tray can be provided with or without holes. Optional dehumidifying fan.

4. Model including features a special trolley layout for sites with floor area limits.

Main Technical Parameters and Relevant Explanations

1. Steam, hot water, electric, heat-conducting oil and hot air from a furnace can all be used as the heat source

2. Operating temperature: 50-140°C for steam. Maximum temperature: 150°C.

3. 50-350°C for electricity or infrared.

4. There are automatic and computer control systems for customer selection.

5. The normal pressure of steam will be 0.02-0.8 MPa (0.2-8kg/cm2).

6. The equipped power of the electric heater will be 15kw calculated with Model 1 and the operational power to be used will be 5-8kw/hr.

7. If you have special requirements, please indicate in the order.

8. The price of the non-standard oven can be negotiated.

9. If the operation temperature is more than 140°C or less than 60°C, please indicate in the order.

10. The size of the drying trolley and tray is standardized.

11. The size of drying tray: 460x640x45(mm).