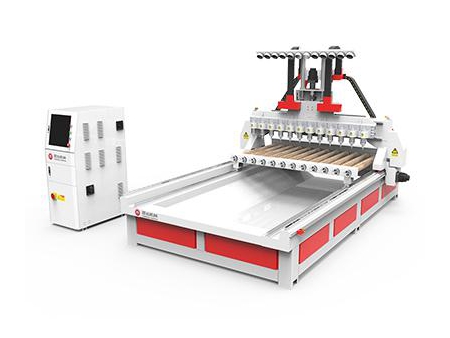

ASC CNC Router

CNC router with automatic spindle changer

- VCT- 1325 ASC2

- VCT- 1325 ASC3

- VCT-1530 ASC3

ASC CNC Router is a specialized power tool that features a high-capacity spindle changer which automatically swaps the spindle in and out of the router. It provides a fast solution for complicated cutting processes that require multiple router tools. With VICUT CNC routing system, operators can perform cutting, milling and 3D engraving operations on woodwork, cabinetry, acrylic stand, signs, guitar and music instruments.

ASC CNC Router Components Explained

1. Base

Made of heavy-duty tubular steel, the base framing is a welded structure precisely machined by gantry milling machine and stress relieved by vibration equipment so that the foundation remains rigid without deformation over the lifetime of CNC engraver.

2. Spindles with Dust Ruffles

Three air-cooled spindles are installed on the router, each delivering a power of 5.5kw, 3.7kwm and 3.7kw. Each spindle is driven by a powerful cylinder for quick lift. Three router tools of different shapes can be applied to every single process. Dust ruffles keep out dust while facilitating tool swapping.

3. CNC System

PC-based controller provides user-friendly interface which allows operators to monitor and control the entire ASC CNC router from a computer. Fast, high-precision motion control can be achieved thanks to the use of CNC display. Differential signal input and output facilitate signal control. Other desirable features include: power failure protection function, linear interpolation, circular interpolation, intelligent pre-fetch (prepared data beforehand for later use), reverse cutting, backlash compensation, breakpoint continuation and block skip, etc.

4. Stepper Motor

High-power stepper motor and gear drive system provide fast machining speed, and exceptional resistance to wear and impact. Synchronous double motors are mounted on Y axis.

5. Electric Cabinet

Enclosed in a mobile double-door electric cabinet are electronic components and a computer. This electric enclosure allows for easy access to and servicing of ASC CNC router when needed. Each wire is attached with a tag so that repair men would easily identify the wiring when service is required.

6. Gear Rack, Linear Guide

VICUT ASC CNC router uses precision gear racks for both X and Y axes, ensuring high speed without vibration. PMI or HIWIN square guide rails are also utilized to guarantee high accuracy.

7. Vacuum Table, Vacuum Pump

Multi-zone vacuum table allows operators to switch on or off one or more vacuum zones so that the whole table area or only part of it can be involved in the engraving process. Gasket cords can be adjusted to seal the perimeter of work-piece of various sizes and shapes. Aluminum alloy can be used to construct the vacuum fixture.

8. Central Lubricator

Central lubricator makes it easier to lubricate guide rails regularly. Just pull the lubricator gently and oil will go where it is needed.

9. Tool Sensor

Smart tool sensor allows for automatic tool length calibration, easy and accurate setting of "Z" zero position, and single and multiple tool changes through programming, which saves time and is error-free.

10. Photoelectric Limit Switch

More sensitive and durable than traditional mechanical switch, maintenance-free for long term use.

11. Foot Pads

Foot pads make it easier to level the ASC CNC router accurately.

Technical Data

| Model | |||

| Working Size | 1300×2500×150mm | 1300×2 50 0× 150mm | 1500×3000×150mm |

| Spindle Power | Water cooled 3kw× 2pcs | Air Cooled 4.5kw ×3pcs | Air Cooled 4.5kw× 3pcs |

| Driver | Stepper Motor | ||

| Tool Diameter | Ø4, Ø6, Ø8, Ø12mm | ||

| Structure | Square Cast Tube | ||

| Transmission | X and Y Axes: gear rack, Z-Axis: high accuracy ball screw | ||

| Guide Rails for X, Y and Z Axes | PMI Square Rails | ||

| Machining Accuracy | <0.03/300mm | ||

| Engraving Speed | 12000mm/m | ||

| Spindle Speed | 6000~240000rpm | ||

| Data Transmission | Connect with PC directly (Original CNC display) | ||

| File Format (programming language) | G code or HPGL | ||

| Voltage | AC220V/50HZ or 380V/60Hz | ||

| Net Weight | Around 1100kg | Around 1300kg | |

| Packing Size | 3860×2230×1600mm | 4360×2430×1600mm | |

Optional Parts: (which are necessary for cutting high-gloss acrylic)

1. Servo Motor

Panasonic AC servo motor is selected for smoother motion and triple working speed, requiring no regular maintenance.

2. Helical Gear Rack, Gear Reducer

Imported from Germany, the top-notch helical gear rack makes cutting more smooth and precise. Gear reducer lessens vibration during cutting.

3. Mist Sprayer

Use alcohol or other coolants to spray mist to the tools during cutting, which makes the cutting edge smoother.

Samples workable with ASC CNC router