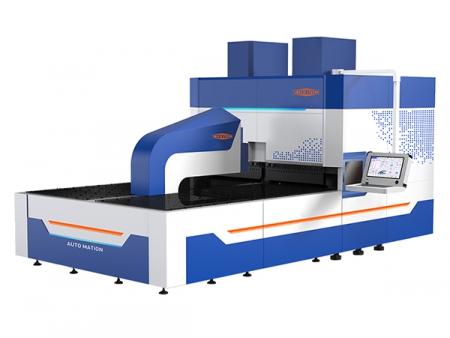

Fully Automatic Bending Center

The flexible bending center is designed to tackle complex sheet metal forming and bending challenges. Utilizing multi-axis parallel motion, it automates the entire bending process, eliminating reliance on manual labor and extensive tooling, significantly enhancing production efficiency while reducing costs.

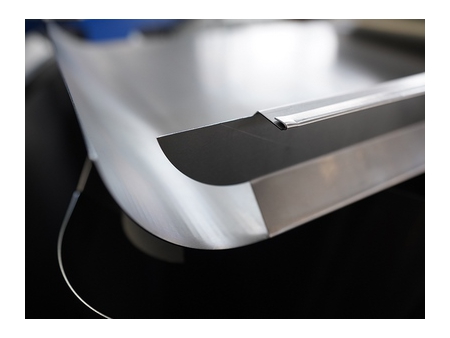

This system easily handles curved, hemmed, and closed-shape bends, meeting the demands of intricate sheet metal applications.

The flexible bending center is widely used in industries such as steel cabinet enclosures (file cabinets, tool cabinets, protective covers, electrical cabinets, telecom enclosures, gas meter boxes, and water meter enclosures), kitchen appliances (refrigerators, air conditioners, stoves), furniture, ventilation, refrigeration, cleanroom doors, architectural doors, decorative materials (aluminum curtain walls), elevators, and other metal forming sectors.

- Material Stainless steel, carbon steel, alloy steel, copper alloy, aluminum alloy

- Length 100-3200

- Width 10-1500

- Thickness 0.5-20

- Angle 0-180 degrees

- Accuracy 0.1-0.3

- Shapes complex shapes of various combinations such as right angles, non-right angles, arcs, upper and lower folds

| Max. bending size (L*W) (cm) | 100* 100 | 140* 125 |

| Max. bending speed (s/bend) | 0.2 | 0.2 |

| Max. bending height (mm) | 170/210 | 170/300 |

| Min. bending thicess (mm) | 0.15 | 0.15 |

| Min. four-sided forming size (mm) | 200*280 | 200*280 |

| Single-sided forming (mm) | 150 | 150 |

| Rated voltage (V) | 380 | 380 |

| Max. bending thicess (mm) | Stainless steel: 1.0 Carbon steel: 1.2 Aluminum: 1.5 | Stainless steel: 1.2 Carbon steel: 2.0 Aluminum: 2.5 |

| Dimensions (L*W*H) (cm) | 310* 150*280 | 350*200*280 |

| Max. bending size (L*W) (cm) | 100* 100 | 140* 125 | 160* 125 | 200* 150 | 250* 150 | 320* 150 |

| Max. bending speed (s/bend) | 0.2 | 0.2 | 0.2 | 0.3 | 0.5 | 0.6 |

| Max. bending height (mm) | 170/210 | 170/300 | 170/300 | 170/300 | 170/300 | 170/210 |

| Min. bending thickness (mm) | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 |

| Min. four-sided forming size (mm) | 200*280 | 200*280 | 200*280 | 200*280 | 200*280 | 200*280 |

| Single-sided forming (mm) | 150 | 150 | 150 | 150 | 150 | 150 |

| Rated voltage (V) | 380 | 380 | 380 | 380 | 380 | 380 |

| Max. bending thickness (mm) | Stainless steel: 1.0 Carbon steel: 1.2 Aluminum: 1.5 | Stainless steel: 1.2 Carbon steel: 2.0 Aluminum: 2.5 | Stainless steel: 1.2 Carbon steel: 2.0 Aluminum: 2.5 | Stainless steel: 1.2 Carbon steel: 2.0 Aluminum: 2.5 | Stainless steel: 1.2 Carbon steel: 2.0 Aluminum: 2.5 | Stainless steel: 1.2 Carbon steel: 2.0 Aluminum: 2.5 |

| Dimensions (L*W*H) (cm) | 310* 150*280 | 450*200*280 | 450*250*280 | 510*270*280 | 570*310*280 | 700*380*280 |

- High Precision

Achieves bending accuracy of up to 0.1° and bending length accuracy of 0.1mm, meeting high-end manufacturing requirements and improving product quality.

- Strong Adaptability

Capable of bending various materials and thicknesses, with adjustable depth and angle, allowing for customized processing needs.

- Multi-Angle & Variable Curvature Bending

The flexible bending center supports multi-angle and multi-curvature bending, accommodating complex shape requirements.

- Easy Maintenance

Features a modular design, making maintenance and servicing simple and cost-effective.

- High Automation

Equipped with automated feeding and unloading systems, reducing manual labor, minimizing workload, and improving production efficiency.

- User-Friendly Interface

Designed with an intuitive and easy-to-use control interface, simplifying operation and reducing the learning curve.

- Customizable Solutions

Offers tailor-made flexible bending centers and service solutions based on specific customer requirements.