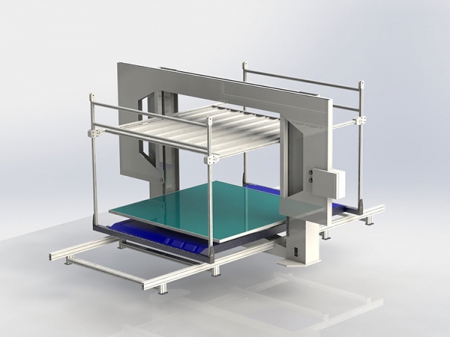

Foam Cutter (Horizontal CNC Contour Cutting Machine, Model GH5)

Uses

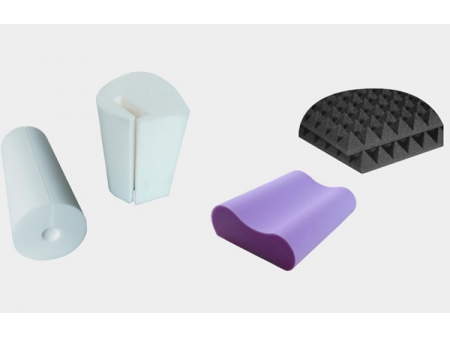

The contour cutting machine can cleanly cut any geometric pattern, which can then be used in almost any industry that uses foam.

Materials suitable for cutting

Polyurethane, HR CMHR, PU flexible foam, sticky foam, latex, Basotect, rebond foam, frame foam, polyethylene.

Shapes

This efficient machine can out blocks, 2D and 3D products, wavy, curved and other regular or irregular shapes.

| Standard | Option | |

| Length of the foam block | 2200mm | 2300mm |

| Height of the foam block | 1250mm | 1500mm |

| Width of the foam block | 2200mm | 2300mm |

| Work table | Rotate 90 °, Rotating work table | |

| AC power | 380V 3 phase 4 wire | |

| Total power | 15KW | |

| Cutting precision | ±1mm | |

| Cutting tool | - Pressure of the knife is 6 bar - Revolving Blade - Size of the knife is 13090mm×3.2mm×0.6mm - Linear speed is15m/s | |

| Operating option | -modem (can do remote diagnosis and maintenance ) -man controlled rotating work table -automatic programming software -computer console -absolute value control system -automatic angle adjustment | |

| Max cutting speed | Depending on different materials, the max cutting speed is30 m/minute | |

Come to see our GH3 model foam cutter, which is a horizontal CNC Contour Cutting Machine, with a highly reliable operating system. As a versatile foam cutter, it can process foam blocks in any size and from different materials, such as memory foam, cleaning foam and latex. Its edit control integrative system can be configured as well.

In comparison to a conventional manual and CNC cutters, the GH3 contour machine has the following advantages:

1. It can cut through soft foam without releasing any dust.

2. It features a high speed oscillating knife control and knife follow system.

3. It his highly precise, and highly efficient.

4. It covers a variety of functions.

5. When in operation, it gives off very little noise.

6. This machine is easy to operate

7. The cutting machine has a beautiful appearance.

8. The GH3 contour cutting machine is great for many types of foam production, and has become the first choice for many companies in the foam industry.

Features

Highly efficient, high automation levels, meets basic requirements

The rotary work platform can automatically rotate 90°.

Its maximum cutting speed depends on the material being cut, though its highest speed is 60 m/min.

It can be equipped with an optional loading lifter band that is 2800mm -4000mm.