Toothpaste Tube Filling and Sealing Machine

Soft Tube Filling and Sealing Line, Toothpaste Tube Filling Machine, Automatic Toothpaste Packaging Line, Toothpaste Tube Filler

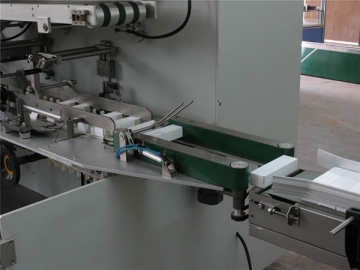

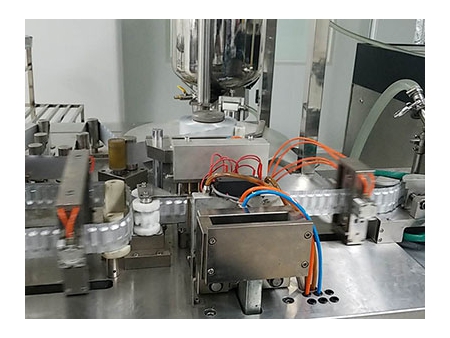

This series of tube filling and sealing machine is used for filling and sealing toothpaste or other similar materials into tubes automatically. We have designed it with a frequency inverter to control the speed, a touch screen for convenient manipulation, a PLC system for automatic control, and a photoelectric sensor to precisely determine the tube position. Once something unexpected happens during running, the tube filling and sealing line will stop and display the reasons automatically. This toothpaste filler and sealer can be used independently or cooperatively with other machines, for example, it is able to complete box sealing when used with a hot melt glue device.

Features

1. This tube filler and sealer features 2 filling heads and a set of double-branch tube feeing system

2. Compact design

3. Fully-closed driving parts

4. Blowing & sucking types tube cleaning devices

5. Pneumatic tube feeding

6. Intelligent temperature control and cooling system

7. Easy-operated

8. 316L stainless steel contact parts (in line with GMP standards)

9. Interlock shutdown when door is open

10. Overload protection mechanism

11. Automatic positioning with photoelectric induction device

12. Tube position control system

13. Acceptable tubes: plastic composite tubes, aluminum plastic composite tube and metal tubes (optional)

Technical Parameters of the Auto Toothpaste Tube Filler and Sealer

Production efficiency: 160tubes /min (max)

Filling volume: 1-300 ml

Filling precision: ≤±0.5%

Tube length: 50-240 mm

Tube diameter: 10-50mm

Power supply: 380V, 50Hz / 220V, 60Hz

Power of hot-wind generator: 3kw

Compressed air consumption: 1.2 m3

Working pressure: 0.6 MPa

Hopper capacity: 70L

Dimension: 2870×1770×2340 mm

| Production capacity (box/min) | 80-200 |

| Max box size (L×W×H) | 200×70×60 mm |

| Min box size (L×W×H) | 75×25×15 mm |

| Box specification | 250-300 g/m2 |

| Max leaflet size (L×W×H) | 260×190 mm |

| Min leaflet size (L×W×H) | 100×100 mm |

| Leaflet specification | 55-65 g/m2 |

| Air consumption | 20m2/h (pressure: 0.50-0.7 MPa) |

| Power of motor (kw) | 2.2kw |

| Power supply | 380V, 50HZ |

| Dimension (L×H×W) | 4380 ×1460 ×1800 mm |

| Weight (kg) | 2500 |

Applications

In household chemical industry: toothpaste, toothbrush, soap, pens, masks, creams, lipstick, and other products packed in paper cartons

In health industry: condoms, and other carton-packed products