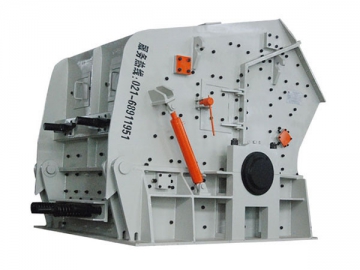

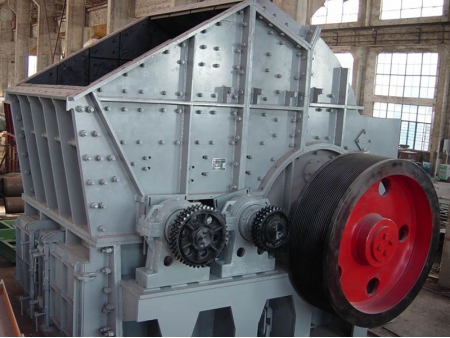

Hammer Impact Crusher, PC-D Series

Impact Crusher, Stone Crusher, Rock Crushing Machine, Limestone Crusher, Cement Crushing Machine

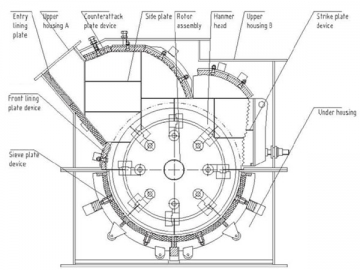

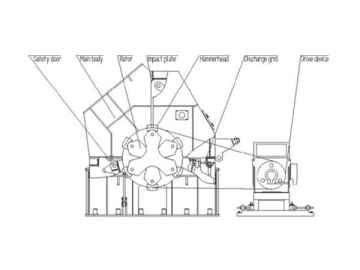

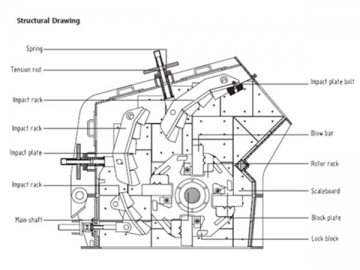

PC-D series hammer impact crusher is a new kind of impact crushing machinery combining the advantages of impact crusher and hammer crusher. It is made up of 3 parts: the upper part, the lower part, and the rotor part. With a unique adjustment device, the granularity and uniformity of the crushed materials can be effectively controlled. Besides, it is easy for users to replace to the hammer and the perforated plate of the hammer impact crusher. New multi-element high-alloy wear-resistant materials are adopted for the consumable parts to ensure the life of the hammer and the perforated plate. This kind of crushing machine features stable running and low power consumption.

Key advantages

1. High efficiency & ultra-long life

Under a same output, the power consumption of the hammer impact crusher is 30% less than that of common ones. The adoption of vanadium-molybdenum multi-element alloy for the adjustable hammer has extended its life for 3-4 times.

2. Super fine crushing & good wear resistance

Additionally equipped with a granularity adjustment device, this stone crusher commits that the proportion of the crushed particles whose granularity are no more than 3mm is over 85%. Life of the hammer and the perforated plate is largely extended since they are made from wear resistant multi-element alloy materials.

3. Large crushing ratio & easy maintenance

This hammer impact crusher is of large crushing ratio. The Grade 1, 2 clinker and Grade 2, 3 limestone can be merged into one grade for crushing. Apart from that, the back cover of the upper chassis can be opened manually or hydraulically for replacing the spare parts.

Applications of the hammer impact crusher

Dongmeng hammer impact crushing machine is widely used in crushing materials with medium hardness such as limestone, cement clinker, shale, dolomite, granite, gypsum, and mixed materials in chemicals, building materials, metallurgy, mining, and coal industries.

| Model | Size of feed opening (mm) | Production capacity (t/h) | Average discharging granularity (mm) | Motor power (kw) | Dimension (mm) | |

| clinker | limestone | |||||

| PC-D-8040 | <80 | 15~20 | 20~25 | 3 | 37 | 1395 ×1506 ×1390 |

| PC-D-8080 | <80 | 25~30 | 30~40 | 3 | 45 | 1395 ×1906 ×1390 |

| PC-D-9080 | <100 | 40~45 | 45~50 | 3 | 45 | 1754 ×1906 ×1659 |

| PC-D-9010 | <100 | 45~50 | 50~55 | 3 | 55 | 1745 ×2176 ×1659 |

| PC-D-1010 | <150 | 50~60 | 60~70 | 3~5 | 90 | 2138 ×2590 ×2021 |

| PC-D-1210 | <200 | 60~80 | 70~90 | 3~5 | 110 | 2524 ×2716 ×2325 |

| PC-D-1212 | <200 | 60~100 | 70~110 | 3~5 | 132 | 2524 ×2866 ×2325 |

| PC-D-1414 | <200 | 70~150 | 70~160 | 5~8 | 200 | 2550 ×3120 ×2670 |

| PC-D-1616 | <200 | 100~210 | 110~260 | 5~8 | 250 | 2922 ×3564 ×2900 |

| PC-D-1818 | <200 | 120~270 | 130~310 | 5~10 | 315 | 3121 ×3754 ×3150 |