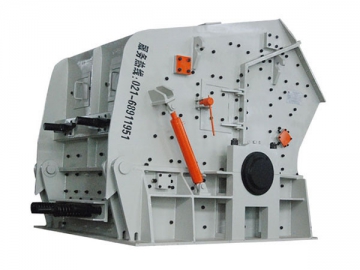

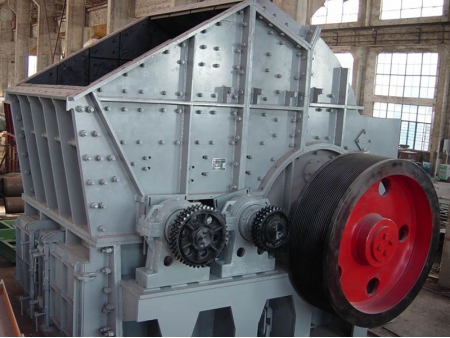

Hammer Crusher, PCF Series

Stone Crushing Machine, Limestone Crusher, Coal Crushing Machine, Plaster Crusher, Hammer Crushing Machine

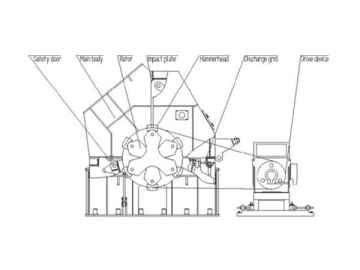

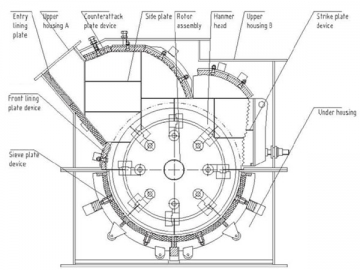

PCF series single-stage hammer crusher is suitable for dealing with limestone whose compressive strength is no more than 200MPa, plaster, coal, limestone, sandstone, shale, and the mixture of limestone and clay. It is equipped with wear-resistance hammer, adjustable crushing plate, safety door, etc.

Key advantages of the hammer crusher

1. Large crushing ratio

This kind of hammer crushing machine is of large crushing ratio. It is able to crush large ores to the required granularity only in one time, which has largely reduced the initial investment and the crushing costs comparing with traditional 2-stage crusher

2. Wear resistant hammer with long service life

The hammer of the crusher is forged using new technique, endowing it with high wear resistance and long life span. The sealing structure of the crusher has validly avoided dust pollution.

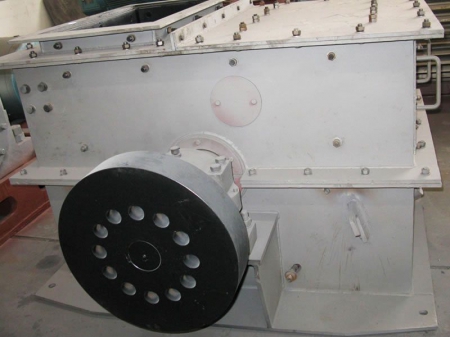

How does it work

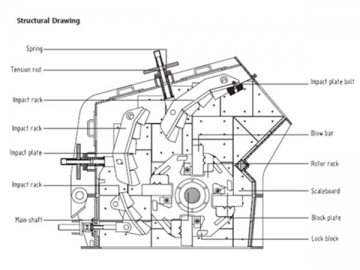

The single-stage hammer crusher with single rotor utilizes a jointed V-belt which is powered by the main motor to drive the rotor equipped with pulley. The ores are fed into the crusher with a heavy-duty ore feeding device and fall on the feed roller which is equipped with shock absorber. The 2 roller running in the same direction will send the ores to the high-speed rotating rotor. After that, the hammers of the stone crusher will crush the ores with a high line speed and throw them to the impact plate for second crushing. The crushing process will continue in the working area of the crushing plate and the grates until the ores' granularity is smaller than the size of the gaps, and then the ores will be discharged from the opening.

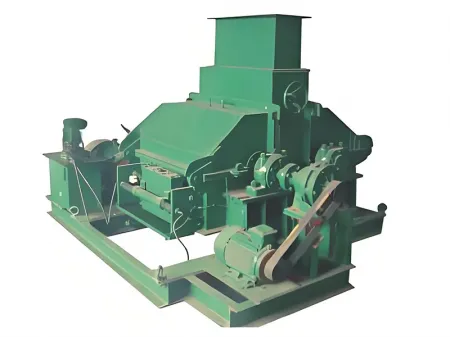

Applications of the hammer crusher

This kind of single-stage hammer crusher is widely used in the industries of mining, building materials, chemical, metallurgy and fodder. It is able to crush materials with middle or small hardness in the secondary or fine crushing process.

| Model | Size of feed opening (mm) | Discharging granularity (mm) | Max feeding granularity (mm) | Rotor length | Production capacity | Motor power | Weight ( with the motor excluded) |

| PCF-1412 | 1290×1320 | ≤25 | 600×600×900 | 1200 | 80-130 | 130-190 | 23.5 |

| PCF-1616 | 1500×1785 | ≤25 | 800×800×1000 | 1630 | 130-240 | 250-350 | 43.3 |

| PCF-1818 | 1750×1840 | ≤25 | 900×900×1200 | 1730 | 240-350 | 400-560 | 70 |

| PCF-2018 | 2268×2130 | ≤25 | 1000×1000×1000 | 1820 | 350-450 | 630-710 | 89 |

| PCF-2022 | 2100×2380 | ≤25 | 1000×1000×1500 | 2230 | 400-600 | 630-800 | 128 |