Lab Visual Inspection Machine

Request a Quote

Automatic Visual Inspection (AVI)

Laboratory inspection equipment for the inspection of ampoules, vials and oral liquid bottles

Technical Specifications

- Speed: 40sec per piece

- Applicable container: 1-20ml ampoules, vials and oral liquid bottles

- Standard inspections: visible foreign particles (glass, metal, fiber, hair, white dots, etc.)

- Particle size: ≥50μm (adjustable)

- Power: 1kW

- Voltage: AC220V, 50Hz

- Worktable height: 900mm

- Machine dimensions (L×W×H): 420×450×600mm

- Machine weight: approx. 100kg

Features

- Stable operation with high inspection accuracy

- Adjustable detection sensitivity to meet specific testing requirements

- Quick and easy format change for different container sizes

Working Principle

The lab visual inspection machine uses machine vision technology to identify visible foreign particles. During high-speed rotation, the product is rapidly braked to a stop, allowing an industrial camera to continuously capture multiple images. These images are analyzed and compared by a computer system to determine whether the product meets inspection standards, and to automatically distinguish between qualified and unqualified items.

Working Process

- Products to be inspected

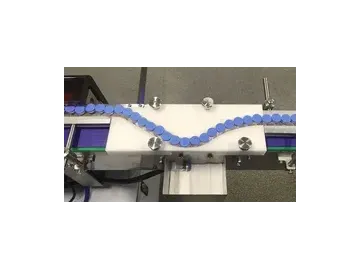

- Bottle infeed

- Photoelectric inspection zone

- Bottle rotation

- Braking

- Image capture

- The separator classifies qualified and unqualified products based on software instructions

- Results are displayed on the screen for both qualified and unqualified items.