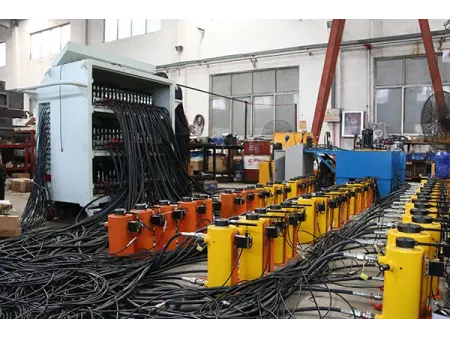

Hydraulic Synchronous Lifting System

PLC multi-point hydraulic motion control system for precise and synchronized lifting of heavy loads

The PLC multi-point hydraulic synchronous lifting system integrates hydraulic technology, sensor monitoring, and computerized automatic control. With a programmable logic controller (PLC) as its core, the system continuously collects displacement and pressure data from all lifting points, executes high-speed calculations, and precisely adjusts the synchronized movement of all hydraulic cylinders. This enables safe, smooth, and coordinated lifting or lowering of large structures.

This system fundamentally transforms traditional lifting operations that rely on manual observation, which often leads to deviations and higher risks. It is now an indispensable tool in modern large-scale construction and industrial installation projects.

| Power Supply | AC 380V/50Hz (Three-phase five-wire system) |

| Display Mode | Human-machine interface (HMI) |

| Max. System Pressure bar | 700 |

| Control Mode | PWM control |

| Control Accuracy mm | ≤±0.5 |

| Pressure Sensing Accuracy | 0.2% |

| Displacement Sensor Resolution mm | 0.004 |

| System Components | 1. PLC multi-point synchronous controller; 2. Synchronous electric pump station; 3. Hydraulic cylinders; 4. Pressure sensors; 5. Displacement sensors; 6. Communication bus; 7. Displacement sensor signal cables; 8. High-pressure hoses |

- Power unit (hydraulic power unit)

- Execution unit (hydraulic cylinder)

- Sensor and detector (displacement/pressure sensor)

- Control unit (PLC control system)

- Hydraulic control components (proportional valve/servo valve)

- Touch screen HMI interface

- High-precision synchronous control: Uses advanced control algorithms, including PID control, to achieve synchronization accuracy of ±0.5 mm to ±1.0 mm, ensuring stable lifting without deformation.

- Real-time monitoring and feedback: Continuously monitors displacement and pressure at all lifting points 24/7. The closed-loop control system automatically corrects any detected deviations.

- Multiple safety protections: Equipped with safeguards against overpressure, underpressure, off-center loads, displacement deviation, emergency stop, and power-loss self-locking to ensure safe operation.

- Centralized intelligent operation: Touchscreen interface provides one-click automated lifting, significantly reducing operator workload and minimizing human error.

- Load balancing control: Automatically distributes force across all cylinders to prevent uneven settlement or shifting loads, protecting both structures and equipment.

- Strong data management: Automatically records, stores, and outputs lifting data curves and reports for full traceability and engineering quality control.

- Modular and scalable design: Supports flexible configuration from 4 lifting points to more than 100 points, adapting to projects of varying size and complexity.

The anchor bolt pull-out tester is used to evaluate the anchoring force (pull-out bearing capacity) of anchors, anchor cables, soil nails, rebars, and similar anchorage elements embedded in rock, soil, or concrete.