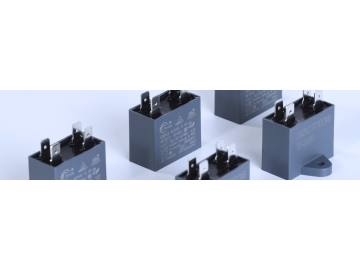

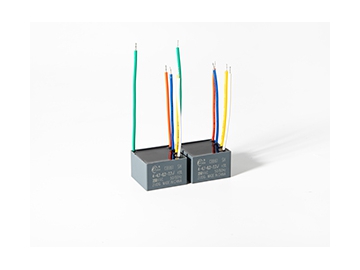

CBB61 Motor Run Capacitor(Metallized Polypropylene Film)

CBB61 electric motor run capacitor includes Terminal Series, Pin Series, Lead Wire Series, Speed Regulation Series. They are all certified to CQC, UL, TUV, and CB certifications.

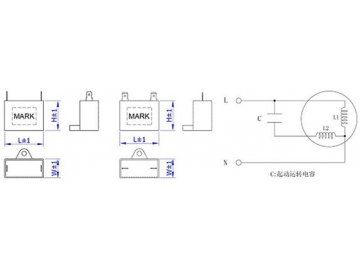

Fan motor or speed governor – lead wire lead-out capacitor, range hood / dish washer capacitor - lead wire lead-out capacitor, air purifier / exhaust fan / air draught / air shower - lead wire lead-out capacitor, bread maker / powder mixer / paper shredder / shoe shine machine - lead wire lead-out capacitor or pin-terminal lead-out capacitor.

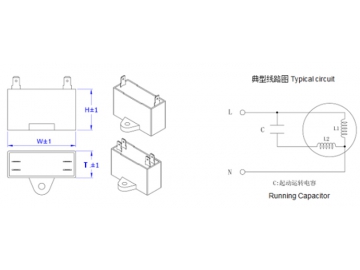

Window-mounted air conditioner, fan - terminal type capacitor

Applications

CBB61 electric motor run capacitor are suitable to start motors for household appliances, such as air conditioner engines, fans, range hooks, large heating fans and more.

| Certification | UL, VDE, CQC, TUV |

| Reference Standard | GB/T3667.1, UL810, EN60252-1 |

| Operation Temperature Range | -40℃~ 105℃ |

| Rated Voltage | 110VAC~600VAC (50/60Hz) |

| Capacitance Range | 0.4μF~30μF |

| Capacitance Tolerance | ±5% (J), ±10% (K) |

| Dissipation Factor (20℃) | ≤0.002 (100Hz) |

| Voltage Proof Between Terminals | 2*UN (VAC)/60s(CQC, VDE, TUV), 1.5*UN (VAC)/60s (UL) |

| Voltage Proof Between Terminals to Case | 2*UN 1000 (VAC) / 60s(≥2000VAC) |

| Degree of protection | CBB61: P0 class; CBB61-P2: P2 class |

| Fault Current | CBB61-P2: 10,000AFC ( UL 810) |

Selection Guidelines

Tab terminal type capacitor: air-conditioning fan/fan

Lead wire type capacitor: fan motor/speed governor

Lead wire type capacitor: rang hood/dish-washing machine capacitor

Lead wire type capacitor: air purifier/exhaust fan /air draught machine

Lead wire type capacitor or pin terminal type capacitor: bread maker/mixer/shredder/shoeshine machine.

| General standards (Unit: mm) | |||||||

| Rated Cap. | 250VAC | 300VAC | 350VAC | 400VAC | 450VAC | 500VAC | 550~600VAC |

| L×W×H | L×W×H | L×W×H | L×W×H | L×W×H | L×W×H | L×W×H | |

| 0.40μF | -- | -- | -- | -- | 31×9×17 | 31×9×19 | 32×11×21 |

| 0.50μF | -- | -- | -- | -- | 31×9×17 | 31×9×19 | 32×11×21 |

| 0.60μF | -- | -- | -- | 32×9×19 | 31×9×19 | 32×12×21 | 33×13×22 |

| 0.70μF | -- | -- | -- | 32×11×20 | 32×11×20 | 32×13×22 | 36×13×22 |

| 0.80μF | -- | -- | 31×9×19 | 32×11×20 | 32×13×22 | 36×11×22 | 37×13.5×24 |

| 1.0μF | 31×9×17 | 31×9×19 | 32×10×19.5 | 36×11×22 | 36×11×22 | 37×13.5×24 | 38×15×25 |

| 1.2μF | 31×9×19 | 32×10×19.5 | 33×13×22 | 36×11×22 | 37×12×22 | 38×15×25 | 39×16×26 |

| 1.5μF | 32×10×19.5 | 32×11×21 | 36×11×22 | 36×12×22 | 36×13.5×24 | 36×15×25 | 38×17×28 |

| 1.8μF | 32×11×22 | 36×11×20 | 36×12×22 | 37×13.5×24 | 38×15×25 | 38×17×28 | 38×19.5×31 |

| 2.0μF | 32×12×22 | 36×11×22 | 36×13×23 | 37×13.5×24 | 38×15×26 | 38×17×28 | 38×19.5×31 |

| 2.2μF | 32×12×22 | 36×11×22 | 36×13×23 | 37×13.5×24 | 36×16×26 | 38×19×29 | 38×22×32 |

| 2.5μF | 32×13×22 | 38×13×23 | 38×13.5×24 | 36×15×25 | 38×17×28 | 38×19.5×31 | 48×19×29 |

| 3.0μF | 36×12×22 | 38×13.5×24 | 38×15×25 | 38×17×28 | 48×17×28 | 47×19×29 | 47×20×31 |

| 3.5μF | 36×12×22 | 38×15×25 | 38×16×26 | 38×17×28 | 48×17×28 | 47×19.5×31 | 48×23×32 |

| 4.0μF | 37×13.5×24 | 38×16×26 | 38×17×28 | 38×19×29 | 48×19×29 | 47×22×33 | 47×23×35 |

| 4.5μF | 37×13.5×24 | 38×19×29 | 38×19.5×31 | 48×17×28 | 47×20×31 | 47×23×35 | 47×25×35 |

| 5.0μF | 37×13.5×24 | 38×17×28 | 48×17×28 | 47×17×31 | 48×20.5×33.5 | 47×23×35 | 47×26×37 |

| 6.0μF | 39×16×26 | 38×19×29 | 38×19.5×31 | 47×20.5×33.5 | 47×23×35 | 47×27×37 | 58×26×38 |

| 6.5μF | 39×16×26 | 38×19×29 | 48×19×29 | 48×19.5×31 | 47×23×35 | 48×28×40 | 58×26×38 |

| 8.0μF | 38×17×28 | 48×19×29 | 47×23×32 | 47×23×35 | 48×25×35 | 58×26×38 | 59×28×40 |

| 10μF | 48×17×28 | 47×20×31 | 47×23×35 | 48×25×35 | 58×26×38 | 59×30×42 | |

| 12μF | 48×17×31 | 47×23×32 | 48×25×35 | 48×28×40 | 58×28×40 | 59×32×43 | |

| 14μF | 48×19.35×31 | 48×25×35 | 47×27×37 | 58×26×38 | 59×30×42 | | |

| 15μF | 47×20×31 | 47×27×37 | 48×28×40 | 58×28×40 | 59×32×43 | | |

| 20μF | 47×23×35 | 58×26×38 | 59×30×42 | | | | |

| 25μF | 47×27×37 | 59×30×42 | | | | | |

| 30μF | 58×26×38 | 59×32×43 | | | | | |

Features

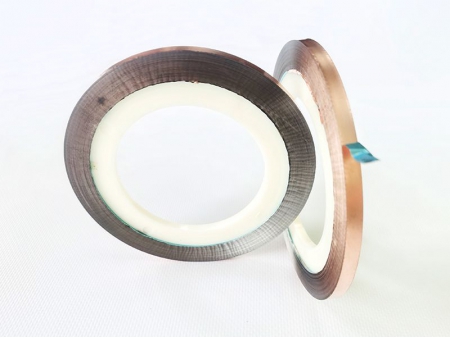

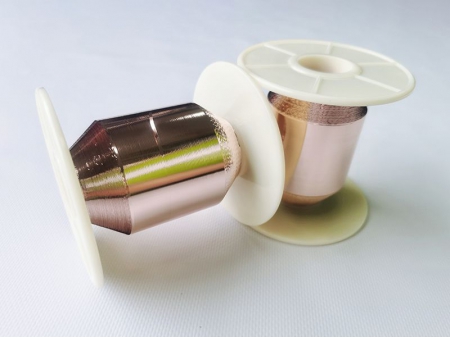

1. Electrician polypropylene film as a medium, zinc-aluminum metallized layer as an electrode, high-quality engineering plastic case, flame retardant epoxy resin for its encapsulating;

2. PVC electronic wire lead-out, strong universality, flexible assembling.

Our Advantages

1. We have supplied capacitors to air conditioning industry for more than 6 years with minimal complaints and one of the lowest replacement rates.

2. Our product certification is complete: (CQC, UL, TUV), allowing us to sell our products to any UL or TUV approved country.

3. Imported materials and stable performance.