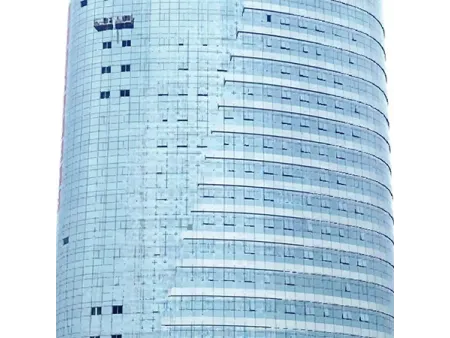

Curved Tempered Glass for Building

- Large Arc Length: Arc length up to 7000mm, height up to 3300mm, radius 3000mm

- Small Radius: Radius as small as 600mm, arc length 1600mm, height 3300mm

- Reverse Curved: Arc length 3200mm, height 7000mm, radius 2000mm

- Multiple Radius Curved: Arc length 2800mm, height 5000mm

-

High Safety: After tempering, the glass shatters into small, uniform particles without sharp edges, reducing the risk of injury.

-

Strong Impact Resistance: The specialized processing enhances the glass's ability to withstand high-impact forces.

-

Excellent Thermal Stability: Curved tempered glass can endure temperature fluctuations without breaking.

-

Strong Wind Pressure Resistance: Ideal for use in high-wind environments, such as building facades in tall structures.

Can i use curved safety glass for building facades or windows?

Yes, curved safety glass is commonly used in commercial building glass facades, curved windows for high-rise buildings, exhibition halls, museums, and other architectural structures with unique shapes. It’s also ideal for applications such as canopies and conservatories with curved designs.

What is the maximum size and radius of curved low-e tempered glass that can be processed?

We can process curved low-e tempered glass with a maximum arc length of 7 meters and a height of 3.3 meters.

Can i get a custom design with multiple curves for my project?

Absolutely! We can create custom designs with multiple curves tailored to the specific needs of your project.

Is there a specific type of curved glass suitable for automotive applications?

Yes, there is a special type of curved glass designed specifically for automotive applications. It must meet stringent standards for safety, optical performance, and weather resistance.

How does curved heat-treated glass differ from standard flat tempered glass?

Curved heat-treated glass differs from standard flat tempered glass in terms of performance, appearance, and processing methods. Curved heat-treated glass combines the benefits of both curvature and tempering, making it suitable for projects that require both structural aesthetics and safety. In contrast, flat tempered glass is more suitable for general building structures.

What are the key applications for curved tempered glass in modern architecture?

Curved tempered glass is primarily used for building facades, curved glass windows, skylights, light roofs, and spiral staircase railings, offering both aesthetic appeal and functional strength.

What is the minimum radius and smallest arc length you can process for curved tempered glass?

For curved tempered glass, the minimum radius we can process is 600mm, with an arc length of 1600mm x 3300mm.

Bring unique architectural designs to life with our curved tempered glass, offering both aesthetic appeal and unmatched safety. From building facades to custom-designed windows, our glass provides strength, durability, and flexibility. Ready to add a distinctive touch to your project? Contact us today and let’s design something extraordinary!